Advantages and Applications of Sapphire Windows

A Window, in the industrial context, is a transparent optical bulk element, functioning to maximize optical transmission within a certain wavelength range of interest or to shield the interior cores from possible damages like scratches, projectiles, high heat, corrosive substances, etc.

Sapphire Windows excel in windows made from other glass counterparts, especially in the aspects of superior surface hardness, durable qualities, and versatile functionalities. Sapphire the second hardest material that existed on earth, with a Mohs value of 9. The high structural integrity of sapphire contributes to its stable mechanical, chemical, thermal, and dielectric properties. So sapphire windows deliver more reliable performances and are often chosen when extreme conditions are encountered.

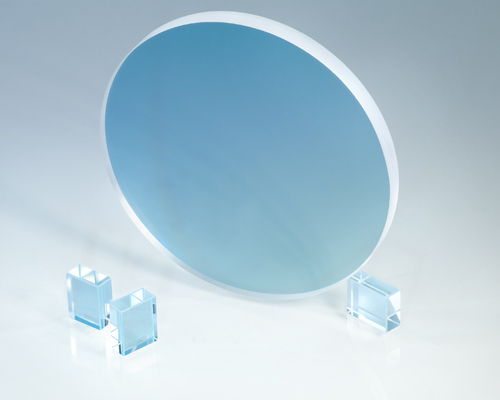

Sapphire Windows from Shalom EO

▶What Are The Advantages of Sapphire Windows

- Outlasting Mechanical Strength: Windows manufactured using sapphire are distinguished for their outstanding mechanical strength. Sapphire windows are resistant to scratches and abrasions and could withstand high pressures. The Young’s Modulus of sapphire is twice as large as the Young’s Modulus of Iron, this means sapphire windows are not prone to shape deformation even great forces are exerted. Therefore sapphire windows are often utilized in high-pressure environments like deep-water glass, or operations that confront frequent abrasions and high-speed projectiles, such as outdoor thermal camera windows, phone screens, laser drilling windows, and aerospace windows.

- Wide Optical Transmission: The transmission spectral range of sapphire is about 225-5500nm, extending from the ultraviolet zone to the infrared region. Compared with UV Fused Silica and N-BK7 windows, Sapphire windows have a wider transparent range, allowing uses in UV, VIS, and IR spectra or multi-spectrum transmission.

- Beneficial Thermal Properties: Sapphire windows feature high thermal conduction and are able to work without being affected under high temperatures with a melting point of 2030℃. Therefore sapphire windows are also a suitable candidate for high-power laser windows, plasma chambers, and combustion chambers.

- Chemical Inertia: Sapphire windows are not reactive to those normal acids and alkalis, with the sole exception being hot caustics. This means sapphire windows are sustainable in corrosive environments, such as the seaside and in the field of chemicals and pharmaceuticals.

▶Applications of Sapphire Windows:

Industrial:

The fierce competition of the industrial sector in the modern era necessitates components of better performance and longer life spans to save replacement costs, a fact that points to sapphire windows. Because of its versatile nature and sturdiness, sapphire windows are applied in numerous industries. Furthermore, sapphire windows could be made much thinner and more compact due to their strong atomic bonds, making them a promising selection along with the high integration trend in the photonic and electric market. In addition, sapphire windows are transparent to a wide range of wavelengths, meaning that sapphire windows could support clear vision as sight windows or the designed transmission rate in some critical optical uses such as lasers after anti-reflection coating.

Examples include laser processing windows, plasma chambers, combustion chambers, furnace viewports, barcode readers, fingerprint lock screens, wristwatches, Infrared Windows, etc.

Here are the reasons:

- High ruggedness that could avoid surface injuries

- Will not deform under high temperatures

- Will not scratch from splatters

- Strong atomic construction enabling greater diameter-to-thickness ratio

- Broad Transmission encompassing UV, Visible, and IR transmission

Medical/Chemical:

In medical and chemical operations, it is crucial to prevent unintended chemical reactions which could hamper the operation or even lead to devastating consequences, so chemical inertia is an essential condition of the equipment components. Sapphire windows are immune to sorts of chemicals, which renders sapphire windows excellent medical and chemical components.

Examples include endoscopic windows, chemical container viewports, etc.

Here are the reasons:

- No out-gassing or formation of chemical products

- Convenient sanitization, being able to endure autoclave treatments

- outperform glass counterparts

Vehicles:

Sapphire windows could be integrated into vehicles as front car windows, and the windows of LiDAR sets of the airplane, which demands unparalleled protection from high-speed collisions with obstacles and various outdoor climates.

Examples include car windows, airborne Lidar windows, aircraft windows.

Here are the reasons:

- High ruggedness to ensure protection from the nuisance of high kinetic energies during driving

- High resistance against humid weather, water, corrosive atmosphere, and extreme climates

- Lightweight and reduced thickness

Defense:

Components incorporated in the defense sector require the highest standard of reliabilities to deal with all kinds of potential threats and emergencies, in the sense of which, sapphire windows are the rational option with unrivaled robustness.

Examples include submarine glass, the front windows of thermal imaging cameras, military-grade laser windows, etc.

Here are the reasons:

- Unrivaled harness to block potential threats

- Stable performance under variable climates

- High thermal loads to withstand explosives and firing

▶Shalom EO’s Sapphire Windows:

Hangzhou Shalom EO specializes in producing and providing sapphire windows with a profound engineering background. We optimize with unceasing efforts customer experience and the stages of sapphire window productions, seeking to achieve the best comprise between qualities and prices.

For off-the-shelf sapphire windows, we offer uncoated circular and square sapphire windows with c-cut orientations and diameters/side lengths up to 150mm. The routine specifications of the stocks are 60/40 S/D and 2 lambda flatness, whilst versions with 40/20 S/D and 1/4 lambda flatness are also accessible.

We also provide various kinds of custom sapphire windows including metalized sapphire windows, wedge sapphire windows, stepped sapphire windows, etc of random, c--cut/z-cut orientations and other custom orientations and tailored coatings. We are capable of manufacturing sapphire windows with 10/5 S/D, and 1/10 lambda flatness upon your request.

Related Articles

Tags: Advantages and Applications of Sapphire Windows