Specifications:

| Materials | CVD ZnS or Multispectral ZnS (Cleartran | )Diameter Range | ~ 250mm |

| Aperture | >90% | Dimension Tolerance | +0.0/-0.2mm |

| Thickness Tolerance | +/-0.1mm | Surface Quality | 60/40 S/D |

| Parallelism | 1 arc minute | Chamfer | 0.3-0.5mmx45degree |

| Coating | AR/AR coating@7-14μm |

Physical and Optical Properties:

| Transmission Range | 0.37 to 13.5 μm | Refractive Index | 2.20084 at 10 μm |

| Reflection Loss | 24.7% at 10 μm (2 surfaces) | Absorption Coefficient | 0.0006 cm-1 at 3.8 μm |

| Reststrahlen Peak | 30.5 μm | dn/dT | +38.7 x 10-6 /°C at 3.39 μm |

| dn/dμ = 0 | n/a | Density | 4.09 g/cc |

| Melting Point | 1827°C (See notes below) | Thermal Conductivity | 27.2 W m-1 K-1 at 298K |

| Thermal Expansion | 6.5 x 10-6 /°C at 273K | Hardness | Knoop 160 with 50g indenter |

| Specific Heat Capacity | 515 J Kg-1 K-1 | Dielectric Constant | 88 |

| Youngs Modulus (E) | 74.5 GPa | Shear Modulus (G) | n/a |

| Bulk Modulus (K) | n/a | Elastic Coefficients | Not Avalailable |

| Apparent Elastic Limit | 68.9 MPa (10,000 psi) | Poisson Ratio | 0.28 |

| Solubility | 65 x 10-6 g/100g water | Molecular Weight | 97.43 |

| Class/Structure | HIP poly-crystalline cubic, ZnS, F42m |

Zinc Sulfide (ZnS) Crystal can be divided into two categories: CVD ZnS grown using chemical vapor deposition, which is a polycrystalline material often used in the LWIR (7 to 14 micro) region of thermal imaging, renowned for their resistance to fracture, superior hardness, chemical resistance, and low cost. There is also Multispectral ZnS (or Cleartran, water-clear ZnS), which goes under a further post-deposition hot isostatic press process after the CVD fabrication, which eliminates the microscopic voids or defects of ZnS, expanding the transmission range from Visible to IR spectra (0.4-14.0μm).

Hangzhou Shalom EO offers Windows made of CVD ZnS and Multispectral Zinc Sulfide (Cleartran). The windows are excellent for FLIR (Forward Looking Infrared). Various custom shapes and anti-flection coatings on two surfaces are available. In comparison, CVD ZnS is harder, although both CVD and Multispectral (Cleartran) Zinc Sulfide have much higher fracture strength than ZnSe and could adapt to applications under extreme conditions (e.g. exterior IR windows on aircraft frames). The multispectral ZnS windows are exceptional for applications throughout VIS and IR regions (e.g. visible cameras, mid and long-wave detectors, and laser rangefinders).

Curves:

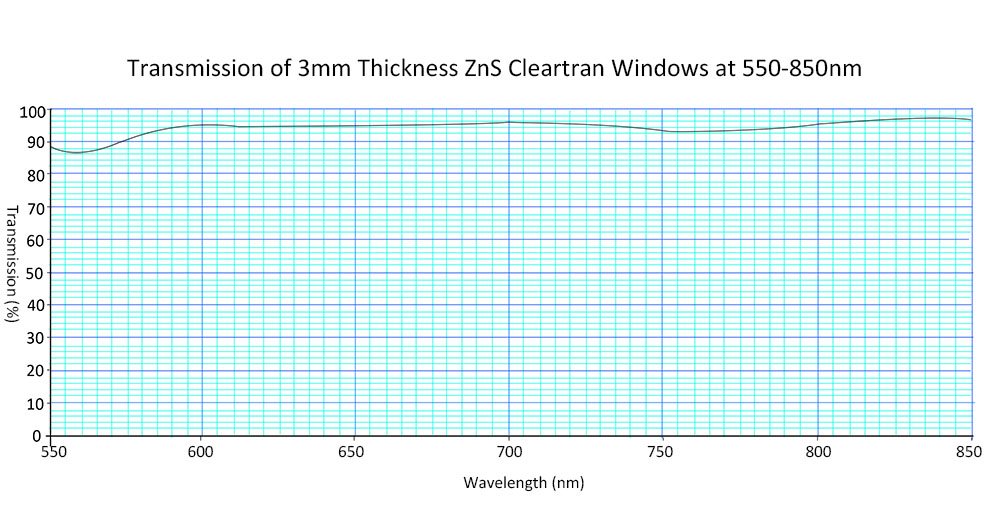

1. Transmission of 3mm Thickness ZnS Cleartran Windows at 550-850nm

2. Transmission of 3mm Thickness ZnS Cleartran Windows at 1000-1100nm

3. Transmission of 3mm Thickness ZnS Windows at 8-12 micro