Specifications:

| Materials | Silicon crystals | Diameter Range | ~ 300mm |

| Aperture | >90% | Dimension Tolerance | +0.0/-0.2mm |

| Thickness Tolerance | +/-0.1mm | Surface Quality | 60/40 S/D |

| Parallelism | 1 arc minute | Chamfer | 0.3-0.5mmx45 degree |

| Coating | AR/AR or DLC/AR |

Material Properties:

| Transmission Range | 1.2 to 15 μm | Refractive Index | 3.4223 @ 5 μm (1) (2) |

| Reflection Loss | 46.2% at 5 μm (2 surfaces) | Absorption Coefficient | 0.01 cm-1 at 3 μm |

| Reststrahlen Peak | n/a | dn/dT | 160 x 10-6 /°C (3) |

| dn/dμ = 0 | 10.4 μm | Density | 2.33 g/cc |

| Melting Point | 1420 °C | Thermal Conductivity | 163.3 W m-1 K-1 at 273 K |

| Thermal Expansion | 2.6 x 10-6 / at 20°C | Hardness | Knoop 1150 |

| Specific Heat Capacity | 703 J Kg-1 K-1 | Dielectric Constant | 13 at 10 GHz |

| Youngs Modulus (E) | 131 GPa (4) | Shear Modulus (G) | 79.9 GPa (4) |

| Bulk Modulus (K) | 102 GPa | Elastic Coefficients | C11=167; C12=65; C44=80 (4) |

| Apparent Elastic Limit | 124.1MPa (18000 psi) | Poisson Ratio | 0.266 (4) |

| Solubility | Insoluble in Water | Molecular Weight | 28.09 |

| Class/Structure | Cubic diamond, Fd3m |

Hangzhou Shalom EO offers Silicon (Si) Windows made from optical grade silicon ( Czochralski or Float Zone Silicon) for IR applications. Silicon windows exhibit good transmission properties in the IR spectrum, in particular in the MWIR and LWIR spectral regions. Due to their high thermal conductivity, Si windows perform great for lasers. In addition, with its low density (2.329 g/cm3, half that of Ge or ZnSe), silicon is conducive to realizing weight-sensitive designs. Silicon features chemical/abrasion resistance, making silicon windows durable and suitable for use in challenging environments ((in fact, it is the hardest material that is transparent to 1000-1600nm light).

The silicon crystal grown using the Czochralski method is excellent for applications in the MWIR (3-5μm) spectrum. After depositing AR coating optimized for the wavelength range, the reflection of CZ silicon windows could be miniature. However, CZ silicon has a strong absorption band at 9μm. Whilst during the production process, Float Zone silicon is doped with Nitrogen and purified to reduce its carbon and oxygen composition, attenuating the absorption at 9μm, therefore FZ silicon windows could be used in the LWIR (8-12μm) range.

Shalom EO offers custom Silicon Windows. The Si windows are available in various custom dimensions, with a maximum diameter of 300mm. Coating options include DLC/AR coating and AR/AR coating.

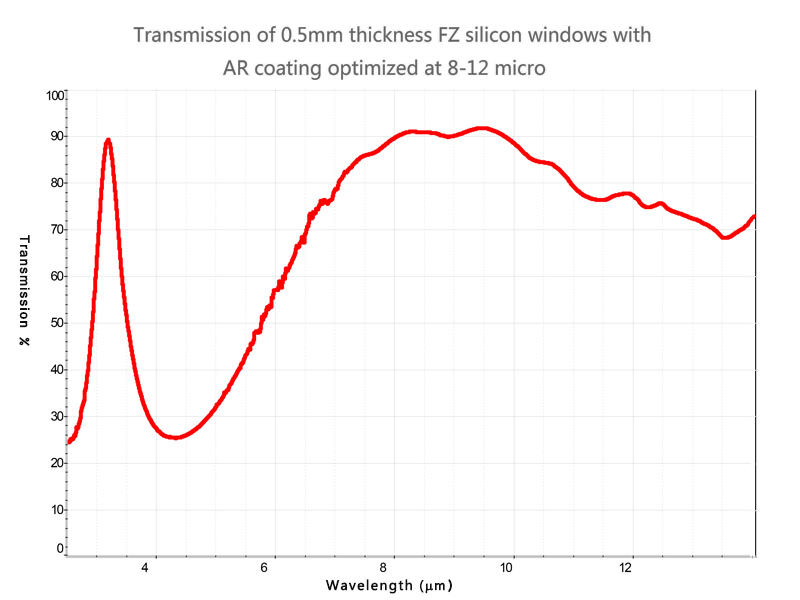

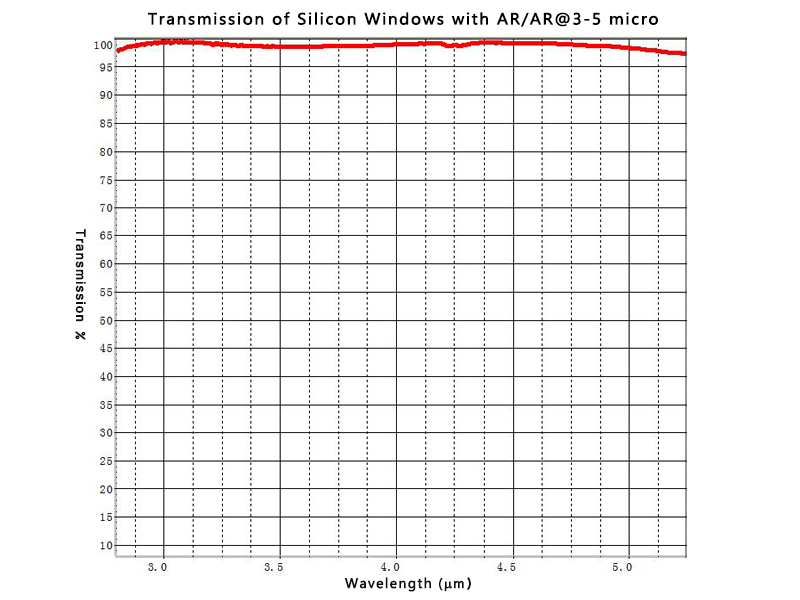

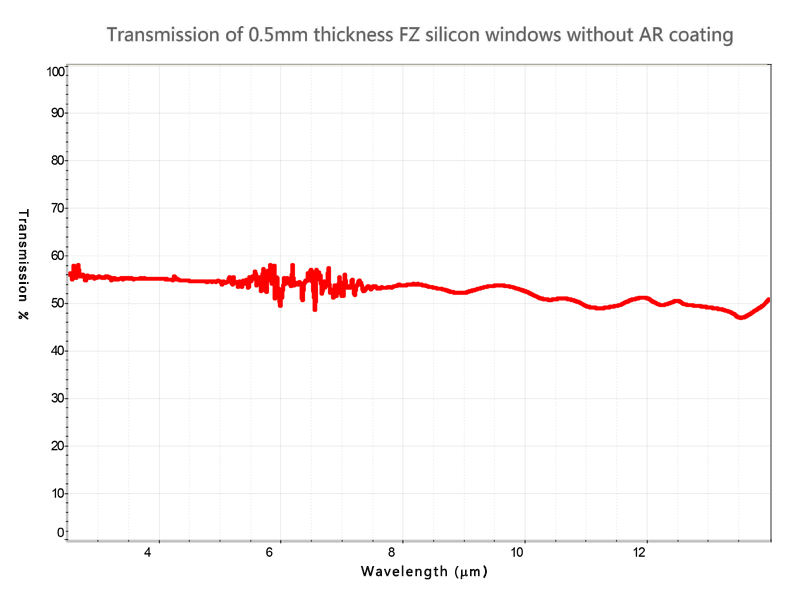

Curves:

1. Transmission curve of the Silicon windows (no coating)

2. Transmission curve of the Silicon windows with AR/AR coating at 3-5μm

3. Transmission of 0.5mm thickness FZ silicon windows without AR coating

4. Transmission of 0.5mm thickness FZ silicon windows with AR coating optimized at 8-12 micro