Polarizing Beamsplitter Cube

A Polarizing Beamsplitter Cube is a solid glass optical element composed of two right-angle prisms, with their hypotenuses attached together to form a cubic shape. A multi-layer dielectric beamsplitter coating of multiple films will be furnished at the interface of the two right-angle prisms. When an unpolarized light hits the PBS cube, it is split into two polarizations perpendicular to each other: the s polarization and the polarization. The dielectric coating reflects the s polarization at 90 degrees and intercepts it, whilst permitting the p polarization to pass and exit. This is how a polarizing beam splitter cube operates. Compared to its cousin, plate beamsplitter, a beamsplitter cube is heavier and more difficult to fabricate large-size ones, however, it does not manifest beam shift effects, and the lengths of the reflected and transmitted light paths are equal, which results in less aberration.

Shalom EO offers Off-the-shelf and Custom Polarizing Beamsplitter Cubes made from ZF Glass. Regarding the standard products, both broadbands polarizing beamsplitter cubes (450-950nm, 650-950nm, 900-1300nm, 1200-1600nm) and laser line polarizing beamsplitter cubes (355nm,532nm,633 nm,808nm,880nm,1064nm,1310nm,1550nm) are available at an extinction ratio of 500:1 or 1000:1 with a beamsplitter coating furnished at the interface of the prisms and anti-reflection coatings at the exits. The dimensions are also diverse, 12.7x12.7x12.7 is available as off-the-shelf versions, while other standardized dimensions including 10x10x10, 15x15x15, 20x20x20, 25.4x25.4x254.4 could be offered upon request. The reflected beam will have an extinction ratio of about 20:1 to 100: 1 depending on the beam splitter.

This page highlights our cemented polarizing beamsplitter cubes, with a damage threshold of 0.2 J/cm2@1064nm, 20ns, 20Hz. We also provide an adhesive-free, optical-contacted, high-power version of the polarization beamsplitter cube. These PBS cubes feature an exceptional LIDT of >15J/cm2@1064nm, 20ns, 20Hz. Click on the bold text to learn more if you are interested.

Application Notes:

1. About the angle of incidence, there are two common alternatives for polarizers made from glass materials: you either project the beam at 45° or at the Brewster angle. However, for polarizers made from crystals such as Glan laser polarizers, the incidence angle could be 0°, 45°, or the Brewster angle. This is because crystal polarizers function using birefringence, but the glass PBS cubes function using dielectric coatings.

2. It is worth noting that the working of the polarizing beamsplitter cube is dependent on wavelength. Furthermore, in the aspect of polarization purity, polarization beamsplitter cubes are far less advantageous than crystal polarizers, for instance, Glan Thompson polarizers exhibit a much higher extinction ratio than PBS cubes.

3. The light should be projected to the side towards to dielectric beamsplitter coating to minimize power passing through the optical cement in order to protect the cement from deterioration.

Figure 1. Shows the working principle of polarizing beamsplitter cubes. First, the incident beam is divided into two orthogonal polarization components, the p component (which is marked in blue in the diagram), and the s component (which is marked in red). At the diagonal of the PBS cube where a polarization-sensitive beamsplitter dielectric coating is tiled, the s component is rejected, while the p component is allowed to exit.

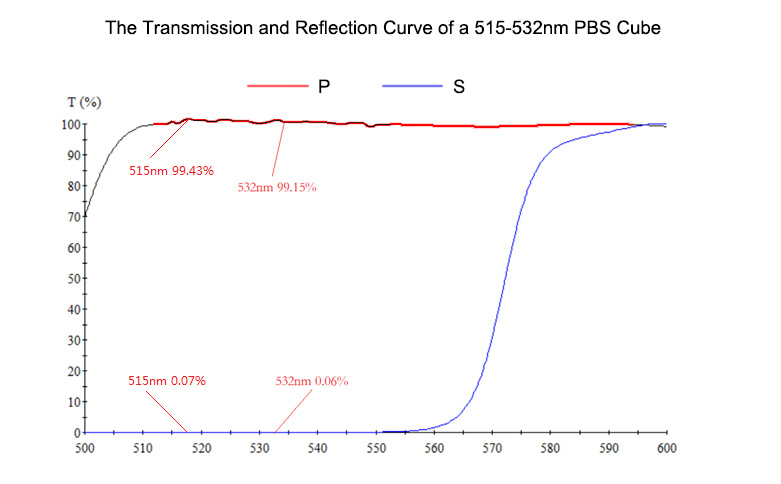

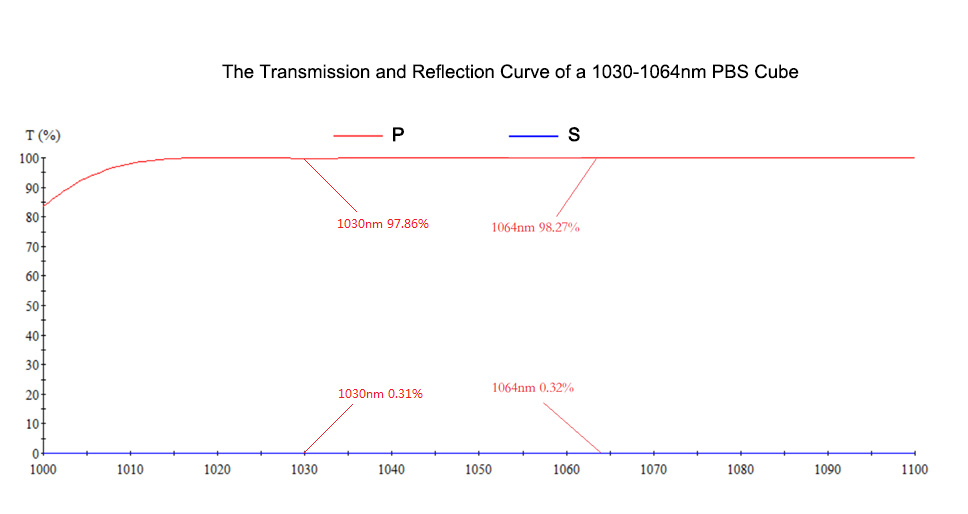

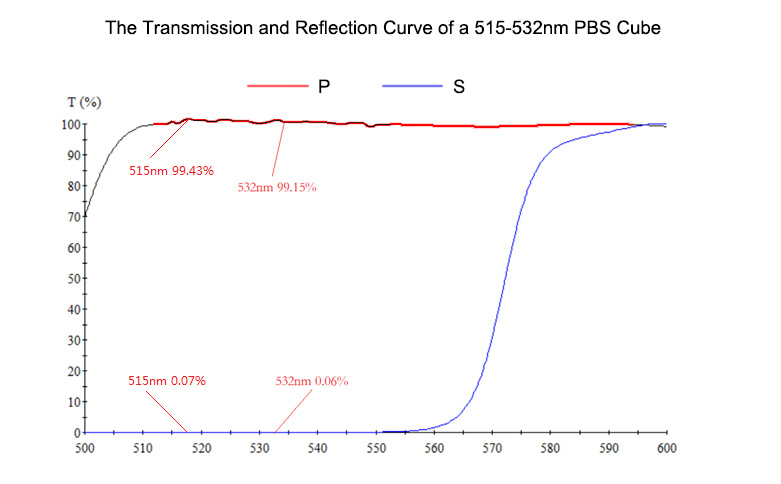

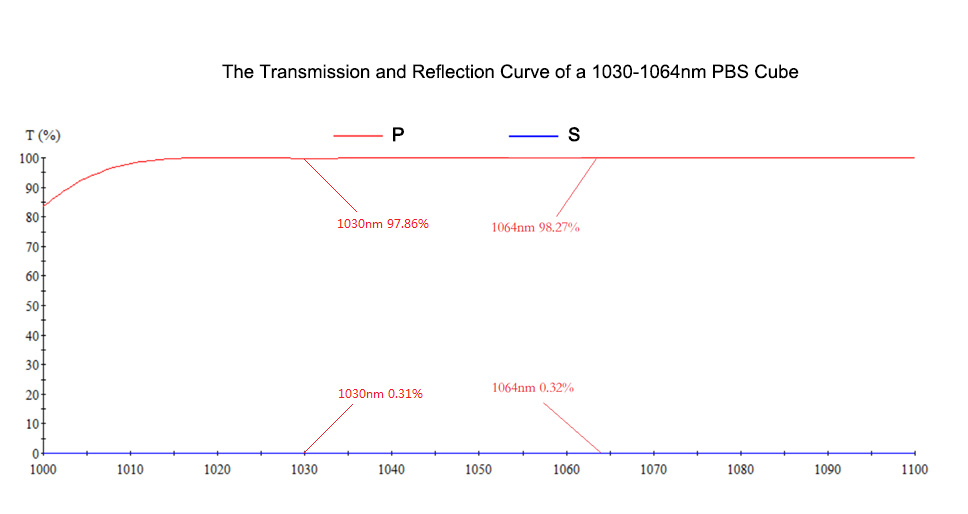

Curves:

1. The Transmission and Reflection Curve of a 1030-1064nm PBS Cube

1. The Transmission and Reflection Curve of a 515-532nm PBS Cube