Specifications:

| Lens Type | Ball lenses, half-ball lenses | Materials | Optical grade single crystal sapphire, ruby |

| Diameter Range | ~300mm | Diameter Tolerance | ±0.02mm |

| Surface Roughness | 0.1μm | Surface Quality | Option: 80/50, 60/40, 40/20 or 20/10 S/D |

| Coating | according to customer's requirement |

Physical and Optical Properties:

| Transmission Range | 0.15-5.5μm | Refractive Index | No 1.75449; Ne 1.74663@1.06μm |

| Reflection Loss | 14%@1.06μm | Absorption Coefficient | 0.3x10-3cm-1@2.4μm |

| Reststrahlen Peak | 13.5μm | dn/dT | 13.1x10-6@0.546μm |

| dn/dμ=0 | 1.5μm | Density | 3.97g/cc |

| Melting Point | 2040℃ | Thermal Conductivity | 27.21 W m-1 K-1 @300K |

| Thermal Expansion | 5.6 (para)& 5.0(perp)x10-6/K* | Hardness | Knoop 2000 with 2000g indenter |

| Specific Heat Capacity | 763 J Kg-1 K-1 @293K | Dielectric Constant | 11.5 (para) 9.4 (perp)@ 1MHz |

| Youngs Modules | 335Gpa | Shear Modules | 148.1GPa |

| Bulk Modules | 240GPa | Elastic Coefficients | C11=496 C12=164 C13=115 C33=498 C44=148 |

| Apparent Elastic Limit | 300 MPa (45000 Psi) | Poisson Ratio | 0.25 |

| Solubility | 98x10-6g/100g water | Molecular Weight | 101.96 |

| Class/Sturcture | Trigonal(hex), R3c |

What are Ball lenses and Half-ball lenses:

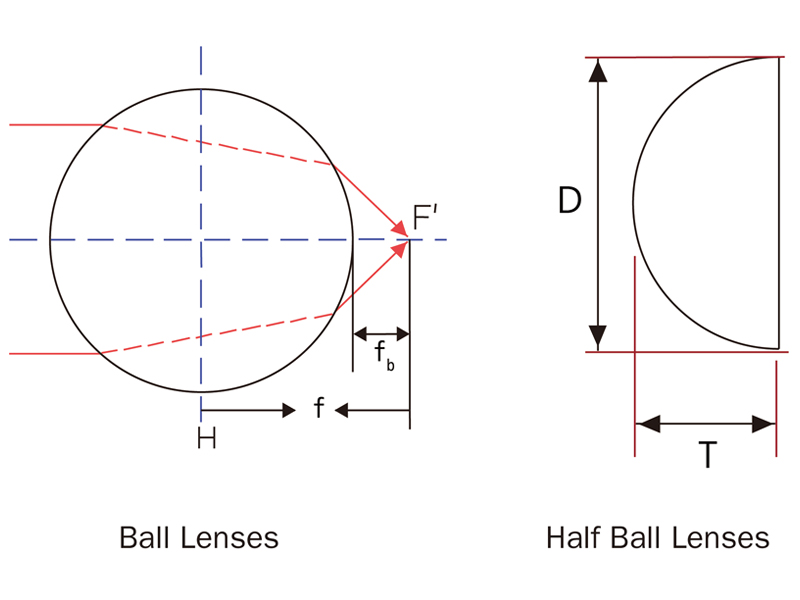

Ball lenses belong to a special form of biconvex lenses which have the geometry of a ball (sphere). They are manufactured from a single optical material with good transmittance in the wavelength region of interest. The conventional applications of ball lenses include focusing light in the field of fibers(e.g. laser to fiber coupling, fiber to fiber coupling), emitters, and detectors, majorly to collimate light depending on the geometries of the input light source. Also, ball lenses could be ball pre-forms of aspheric lenses where they are deformed in order to prevent spherical aberrations.

Half-Ball lenses are variants of ball lenses, obtained through cutting the ball lenses in half. Due to the ease of mounting derived from the one flat surface, half-ball lenses are more convenient for applications where more compact designs are required, such as fiber communication, endoscopes, microscopes, optical pick-up devices, and laser measurement facilities.

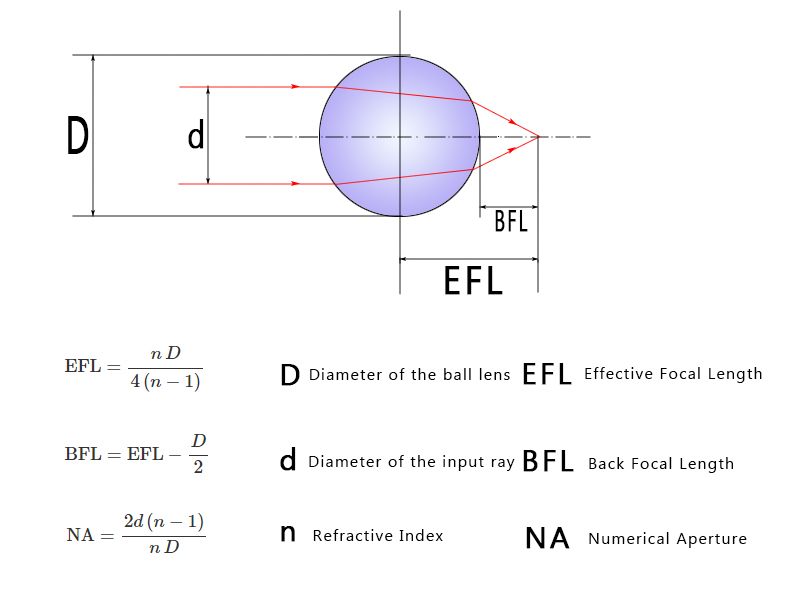

There are three essential parameters of ball lenses and half-ball lenses. One is the effective focal length (EFL), which is the distance between a plane through the center of the lens and the beam waist (focus) of a collimated input beam. Another is back focal length (BFL), defined as the distance of the focal point from the lens surface, therefore half the diameter smaller than the EFL. The last is numerical aperture (NA), for collimated incident light, the numerical aperture (NA) of the ball lens is dependent on the size of the ball lens (D), its index of refraction (n), and the diameter of the input source (d). Numerical aperture is proportionate to the resolution of the lens, the larger the NA, the more the light is collected by the lens.

The calculation equations of the EFL, BFL, and NA and shown in the figure below:

Besides the custom sapphire ball and half-ball lenses, Hangzhou Shalom EO also provides stocked ball lenses and half-ball lenses made from Sapphire. The specifications of the custom ball and half-ball lenses could be varied upon your request. In addition, sapphire lenses of other custom shapes including plano-convex, Plano-concave, meniscus, and double-concave/convex are also available in Shalom EO.

Here are some important features of Sapphire:

Sapphire:

Optical-grade Sapphires chosen to produce optical components are Alpha Single Crystal Sapphires, chemical formula Al2O3, with a wide transmission range from 0.225-5.5μm. Sapphire has a hexagonal structure. The lattice constant is a=b=4.758A, c=12.991A, and the refractive index is 1.762-1.770. Its strong covalent bonds contribute to the enduring and solid nature of sapphire. Its Mohs hardness is 9, ranking right after diamond, and its anti-compression strength is between 1.9-24 GPa. Young’s Modulus of sapphire is 380Gpa, which is about twice the magnitude of irons. The melting temperature of sapphire is high,2045 °C, which enables sapphire to be engaged in manifolds of applications requiring high thermal loads.

Sapphire lenses are ideal for demanding applications because of their eminent performance, consisting of superior surface hardness (9 on the Mohs scale, the third hardest mineral, after diamond at 10 and moissanite at 9.5, which means high resistance to scratch and abrasion), high thermal conductivities, outstanding dielectric properties and resistance to common chemical acids and alkalis. In addition, sapphire features a high index of refraction and excellent broadband transmission characteristics.

Curves:

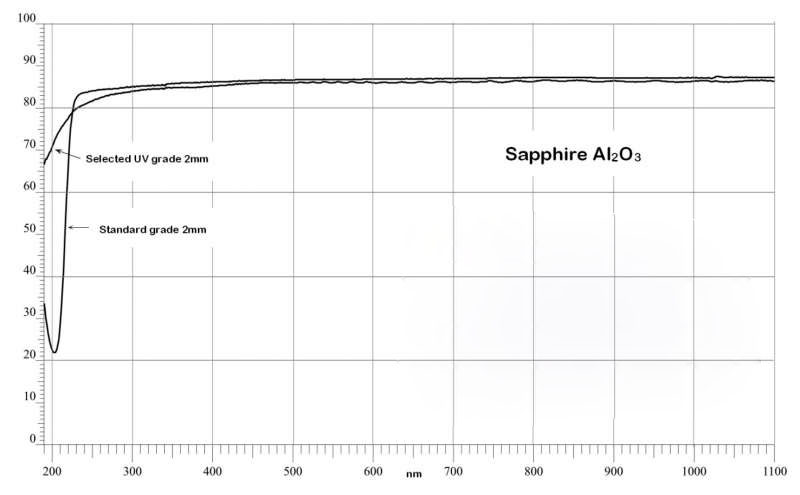

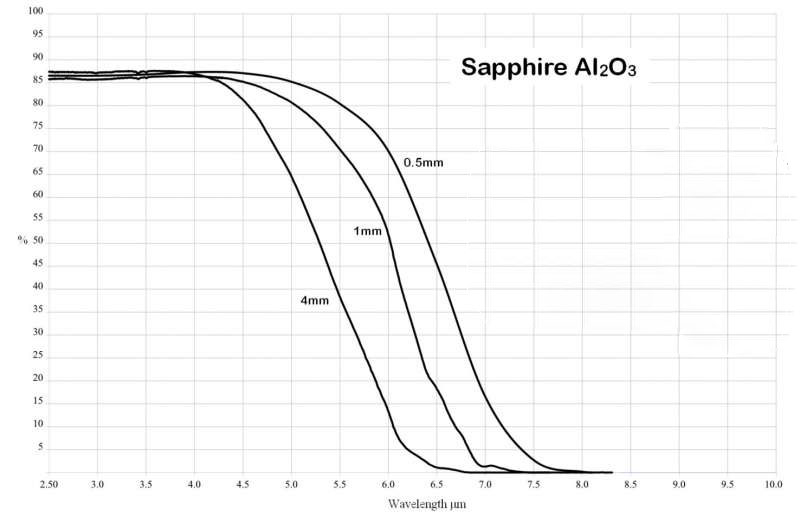

1. Transmission of Sapphire at Infrared wavelength range (no coating)

2. Transmission of Sapphire at UV wavelength range ( no coating)