Spherical Lenses vs. Aspheric Lenses

Introduction

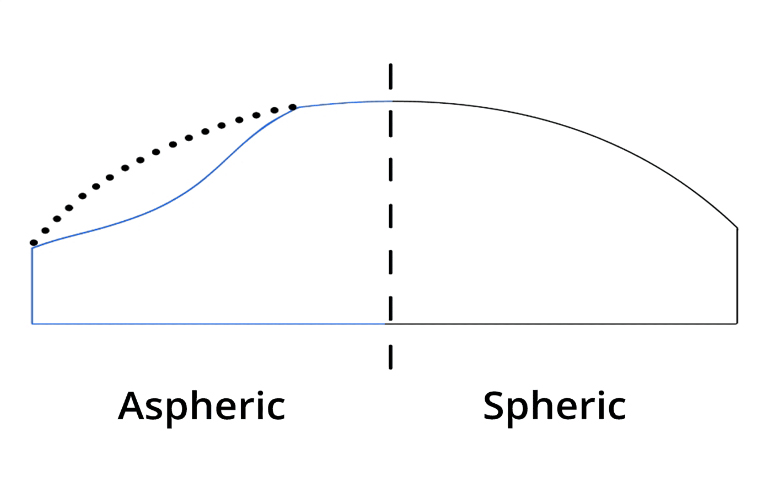

A Spherical Lens is an optical lens with a curved profile that could be regarded as a portion of a sphere. The radius of curvature is constant across the entire lens. The line connecting the spherical center points of the front and rear surfaces of the lens is called the optical axis of the lens. The word aspheric denotes not being a section of a sphere. An Aspheric Lens has a non-spherical but rotationally symmetric surface. Its radius of curvature varies along the center axis.

The most outstanding advantage of aspheric lenses is their capability to correct spherical aberrations. If We take other factors into consideration, such as high image resolutions, large numerical apertures, and compactness of design, the aspheric lenses are also attractive candidates. However, spherical lens retains a competitive edge in ease of product, and lower production cost as well. In this article we are discussing the advantages and disadvantages of spherical and aspherical lenses, making a comparison between the two categories of lenses.

Figure 1. shows the difference between an aspheric lens and a spherical lens.

The Mathematical Description of Aspheric Lens

An aspheric lens is a lens with a non-spherical surface but a radius of curvature that varies radially from the center of the lens.

One common mathematical representation of aspheric lenses is the conic section, which is defined by the equation:

z = Ax^2 + Bxy + Cy^2 + Dx + Ey + F

where x, y, and z are the coordinates of a point on the lens surface and A, B, C, D, E, and F are the coefficients that determine the shape of the surface. By adjusting the values of the coefficients, the lens surface can be designed to correct for specific aberrations.

Another mathematical representation of aspheric lenses is the aspheric polynomial, which is defined by the equation:

z = C(1 + k) * (r^2/R^2) + Ar^4 + Br^6 + Cr^8 + ...

where z is the height of the surface above the optical axis, r is the radial distance from the optical axis, R is the radius of curvature of the surface, C is the conic constant, k is the conic coefficient, and A, B, and C are the polynomial coefficients. The polynomial coefficients can be adjusted to correct for specific aberrations.

The Manufacturing of Aspheric Lens

Compared with spherical lenses, the production process of aspheric lenses is more complicated due to the complex geometries, and different production technologies are suitable for different occasions.

Precision Glass Molding

Precision glass molding is a technique of heating the glass material to a high temperature until it becomes plastic, shaping it using an aspherical mold, and then cooling it down to room temperature. Precision glass molding is not appropriate for aspheric lenses with a diameter greater than 10mm. But new tools, new glass material, and metrology procedures are all pushing the technology forward. Although the cost of precision glass molding is high in the early stage of design (the building of high-precision molds), after the mold is formed, the incremental cost can even out the start-up costs. This technique is in particular suitable for occasions that require mass production.

Precision Polishing

Grinding and polishing are in general utilized for the occasion of producing a single aspheric lens at one time. The aspheres produced using precision polishing are often larger in size than those produced using glass molding. The precision polishing process is controlled by a computer, called CNC (computerized numerical control), with automatic adjustments to optimize parameters. If a higher quality finish is required, magneto-rheological finishing (MRF) will be used. MRF polishing offers higher performance and saves time compared with standard polishing. Precision polishing requires professional equipment and is the first choice for sample production and low-to-medium scale production.

Diamond Turning

This method involves using a diamond-tipped cutting tool to machine the lens material to the desired aspheric shape. Diamond turning allows for precise control of the lens surface, and the surface quality of the lens produced using this method is often higher than that produced using other production methods. Material options are much more limited with SPDT than with other techniques because glass cannot be shaped through diamond turning, whereas plastics, metal, and crystals can. SPDT can also be used in making metal molds utilized in glass and polymer molding.

Polymer Molding

Polymer molding is a technique of putting a spherical lens as the base, then die-casting on the surface of the spherical lens using an aspheric mold and utilizing ultraviolet light to cure the aspheric lens with a film of high-molecular-polymer. Polymer molding in general uses an achromatic spherical lens as the base, and a section of aspheric surface is die-cast on the surface to achieve simultaneous elimination of chromatic aberration and spherical aberration. Polymer molding is suitable for occasions requiring additional characteristics (elimination of chromatic and spherical aberration at the same time) and high-volume manufacturing.

Injection Molding

In addition to aspheric lenses made of glass, there are aspheric lenses made of plastic. Plastic molding is the technique of injecting molten plastic into an aspheric mold. Compared with glass, plastic has poor thermal stability and pressure resistance and needs special treatment to obtain similar aspheric lenses. However, the biggest characteristics of plastic aspheric lenses are low cost, lightweight, and easy molding. Injection molding is extensively hired in occasions with moderate optical quality, insensitive thermal stability, and low pressure resistance.

Figure 2. Aspheric Lenses from Shalom EO

The Advantages of Aspheric Lenses:

Correction of Spherical Aberrations:

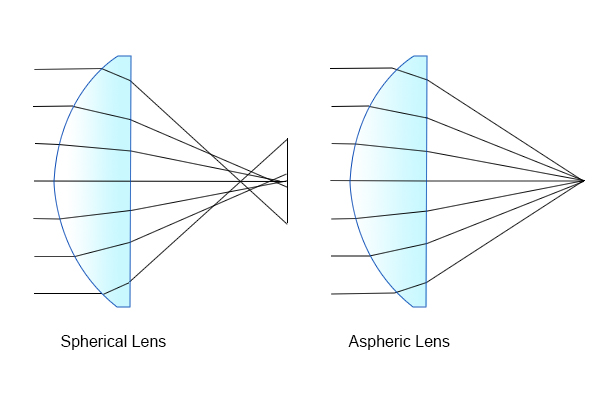

Spherical aberration is the intrinsic failure existing in all spherical lenses and has nothing to do with production tolerances, even a spherical lens manufactured with perfect precision will still exhibit spherical aberrations. It is a phenomenon when light rays that strike a spherical surface off-center are refracted or reflected more or less than those that strike close to the center instead of being focused onto the theoretical focal point, the consequence is a blurring of the spot. Replacing spherical lenses with aspheric lenses is an excellent measure to correct spherical aberration. As shown in Figure 3, the aspheric lens brings the off-center light rays focused onto the focal point, creating a crisp spot. By adjusting the conic constant and aspheric coefficient, any aspheric lens can be optimized to minimize aberrations.

Figure 3. illustrates the correction of spherical aberration using an aspheric lens

Other Advantages of Aspheric Lens

Correction of Chromatic Aberrations:

In general, due to the symmetric shape of the spherical surface of the traditional spherical lens, when a light source composed of different wavelengths is incident, the light will encounter different refractive indices, which will cause chromatic aberration. Aspheric lenses can achieve the correction of chromatic aberration by designing asymmetric curvature radii, so that light of different wavelengths has the same refractive index in the lens, thereby reducing chromatic aberration.

Correction of Image Field Distortion:

Distortion is a variation of the magnification with the field angle, causing changes in the shapes of the image according to the actual object. Distortion has no impact on the image qualities but affects the similarities of the image to the object. When a lens is forming an image, it will deform or distort the objects at the edge of the image, Aspheric lenses can be designed with asymmetric curvature radii so that lights at different positions have the same refractive index in the lens, which can better correct image field distortion or distortion.

Achieving Larger Numerical Aperture and Higher Resolution

In the case of a spherical lens, a common measure to obtain the desired resolution is to reduce the numerical aperture (increase the f/#) of the lens group. The result is a trade-off of the loss of light throughput. Aspherical lenses allow the achievement of high image resolution without sacrificing the numerical aperture.

Simplification of Optical System

A single aspheric lens could substitute a dozen of spherical lenses because the former offers manifold correction of optical aberrations at a time. This permits the simplification of the system, leading to a reduction in production coat. Furthermore, in application contexts where capacity and weight might be of concern. aspheric lens is far more advantageous than spherical lenses. For instance, aspheric lenses could be used to downscale modern fluorescence microscopes, projectors, or lasers. the use of aspheric lenses has played a decisive role in the aerospace field with its benefits of weight-saving and downscaling. By reducing weight, fuel consumption can be reduced when sending Earth observation satellites.

The Advantages of Spherical Lens

Simple Design and Manufacturing Process:

Aspheric lenses require a more complex design and manufacturing process compared to spherical lenses, which can lead to higher costs. Whilst spherical lenses have a clear advantage in terms of production costs thanks to their simple geometry. The spherical shape ensures an easy manufacturing process and shorter production times, especially for products with small diameters. Spherical lenses can be fabricated using entirely mechanical rather than computer-controlled apparatus. Depending on the lens size and the quantity desired, spherical lenses can often be polished in batches, saving considerable time in setting up the polishing process.

Alignment and Tolerance Requirements:

Aspheric lenses have strict alignment and tolerance requirements during the manufacturing process, which can result in increased production costs and reduced yields. Whereas spherical lenses tend to have fewer concerns about these.

Broad Availability:

Aspheric lenses may not be available in certain sizes or configurations, which can limit their use in certain applications. The spherical lenses feature broader availability than the aspheric lens and have a wide range of applications Due to the combination of low manufacturing costs, fast production times, and a wide range of optical applications, spherical lenses are an integral part of the optical market and excel in a high price-performance ratio.

Correction of Optical Aberrations

Correction of Optical aberrations can be realized by combining and matching several lenses, the same correction effect could be achieved as in the case of using aspheric lenses. For example, achromatic aberration could be eliminated by integrating achromatic doublets into the lens group. Spherical aberration could also be mitigated by deliberately arranging singlet spherical lenses. And as the production costs of spherical lenses are lower than that of the aspheric lenses, even though more lenses might be required, the total cost might still be lower.

Evaluations:

Aspherical lenses have strengthful functions encompassing correction of spherical aberrations, chromatic aberrations, and distortions, and are advantageous to maintain the light throughput and downscale the lens group. However, the manufacturing process of the aspheric lenses is complex as it requires the supervision of a computer, and the production cost is also high. Spherical lenses are relatively low in cost because they are easy to manufacture in batches.

However the issue of cost cannot be generalized, aspheric lenses allow optics designers to use fewer optics to correct for aberrations than traditional spherical elements because the former provides more aberration corrections than the latter uses multiple elements. For example, a zoom industrial lens that in general uses ten or more lens elements can use one or two aspherical lenses to replace five or six spherical lenses and can achieve the same or higher optical effects, reduce production costs, and reduce The size of the system.

Optical systems employing too many optical elements can have adverse impacts on optical and mechanical parameters, resulting in more expensive mechanical tolerances, additional calibration steps, and more AR coating requirements. All of these consequences ultimately reduce the overall usefulness of the system. Therefore, whether to integrate aspheric lenses or spherical lenses into the system design depends on the actual design requirements and the balance of the two solutions.

Tags: Spherical Lenses vs. Aspheric Lenses