Chalcogenide Glass

Chalcogenide Glass is a kind of covalently bonded glass material manufactured from elements in the VIA group (Chalcogens, including: Sulfur, Selenium, Tellurium, except O), in combination with other elements like As, Ge, P, Sb, Al, Si. Chalcogenide Glass features high optical transmission in the Midwave Infrared (3-5 micro) and Longwave Infrared (8-12 micro) wavelength region, in particular in the LWIR spectrum, the average transmission is above 64, while with anti-reflection coatings its LWIR transmission could be further leveraged to 95%. Therefore chalcogenide glass is becoming a strong contender in the fields of IR applications.

In comparison with other Infrared crystal materials such as Germanium, Zinc Sulfide, Silicon, Zinc Selenide, etc., Chalcogenide glass has the advantages of: 1. Low Thermal Coefficients of Refractive Index, hence requisite for producing the heat-insensitive athermalized lenses and rectification of chromatic aberrations. 2. Ease of processing. Chalcogenide glass has a lower softening point and mechanical hardness than common crystal materials, therefore could be processed into various optical components more efficiently. 3. Low Preparation cost. Fabricating Chacogenides Glass needs to consume much less Germanium, and its ingredient cost is approximately 1/4 of that of Germanium crystal.

Along with the development of LWIR Thermal Imaging configured with Uncooled FPA detectors, lenses made from Chalcogenide glass are emerging as a major role in an extensive range of industries and domains, including gunsight, missiles surveillance, security, etc. Athermalized lens assemblies of lightweight and compact architecture for thermal cameras could be obtained using Chalcogenide glass, as a means of passive optical athermalization. In contrast to active athermalization which utilizes cumbersome mechanical structures, passive optical athermalization exploits the thermal-consistent refractive properties of Chalcogenide glass, therefore eliminating the impact of thermal defocus within a certain temperature range, the design is simple and concise. It is also feasible, using high precision molding, to realize bulk production of aspheric Chalcogenide glass lenses, which are useful for developing systems with reduced chromatic aberrations, and even achieving achromatic performances, thus enhancing the image quality.

Since the 1950s, glass and material elites such as SCHOTT, VITRON, UMICORE have developed matured fabrication technologies of Chalcogenide glass. However, over the past decade, Chinese manufacturers like NHG have also established a series of Chalcogenide glass codes that are popular in the global market. Shalom EO offers Lenses and Balls made from different codes of Chalcogenide Glass. Shalom EO sources the NHG chalcogenide glass (the IRG series) as the major substrate material, including IRG201, IRG202, IRG203, IRG204, IRG205, IRG206, and IRG207. There are chemical/optical/thermal properties, and the equivalents from SCHOTT, VITRON, UMICORE, PIKE, etc.

Glass Codes Cross-reference Chart:

| NHG | VITRON | PIKE | UMICORE | SCHOTT |

| IRG201 | IG2 | AMTIR-1 | IRG22 | |

| IRG202 | GASIR-1 | |||

| IRG203 | GASIR-2 | |||

| IRG204 | IG2 | AMTIR-1 | IRG22 | |

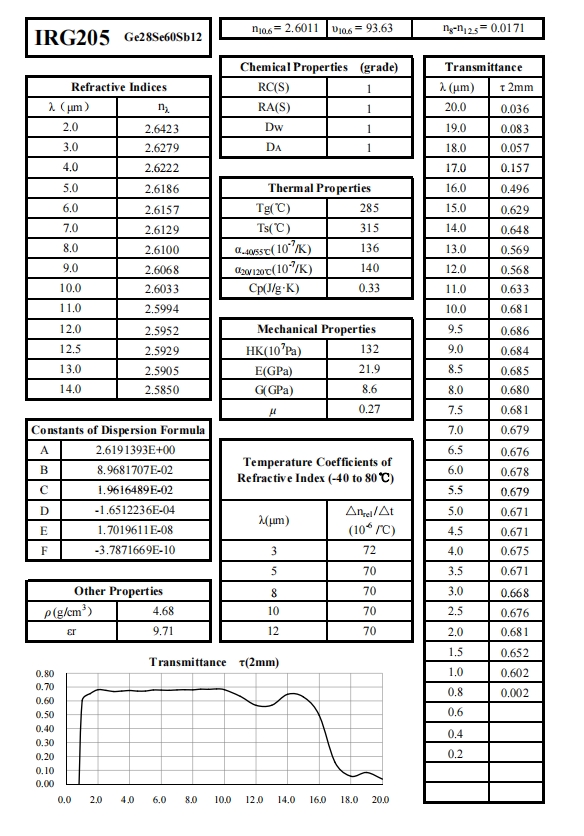

| IRG205 | IG5 | AMTIR-3 | IRG25 | |

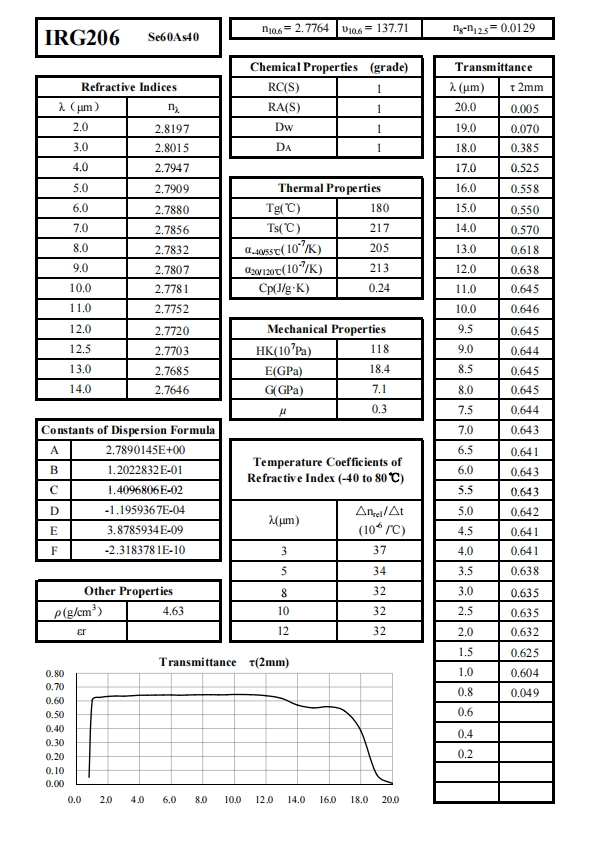

| IRG206 | IG6 | AMTIR-2 | GASIR-5 | IRG26 |

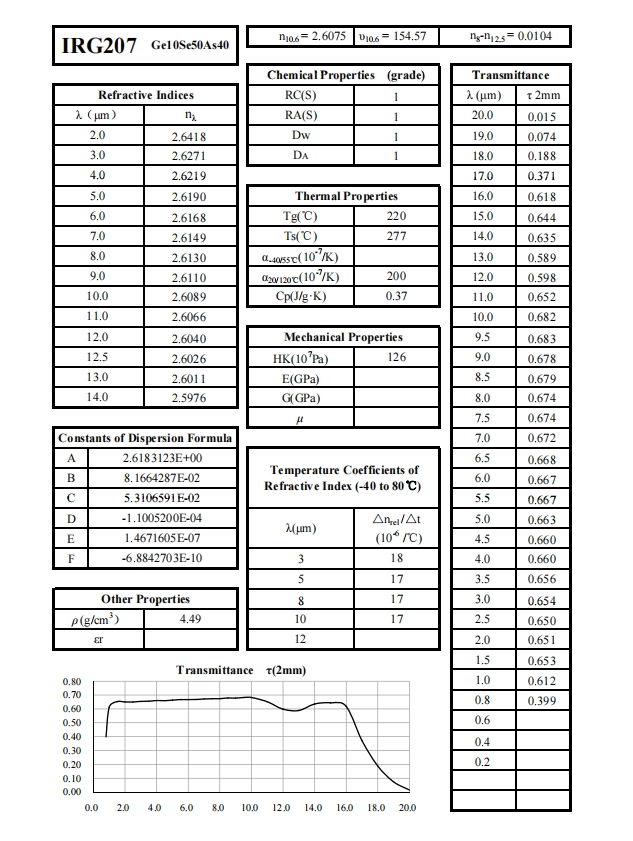

| IRG207 | IG4 | IRG24 |

Properties of IRG Series from NHG:

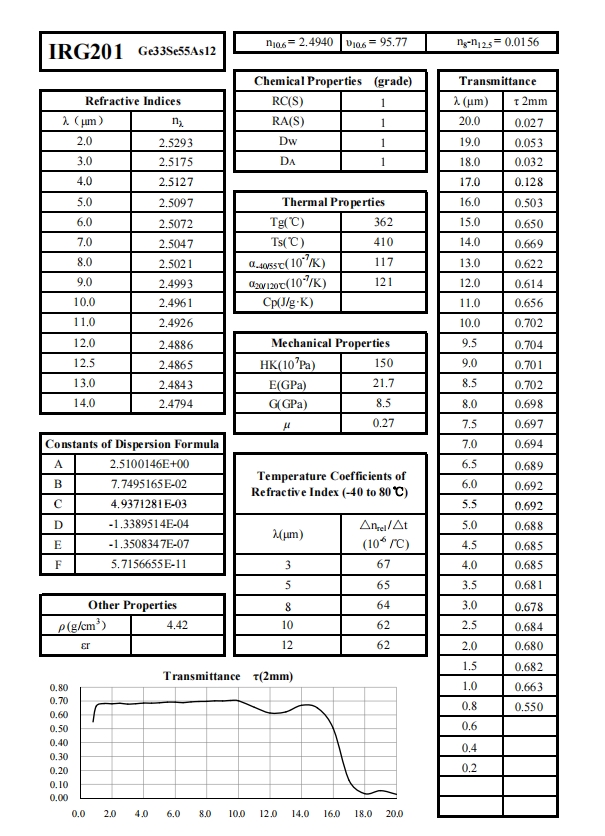

1. IRG201

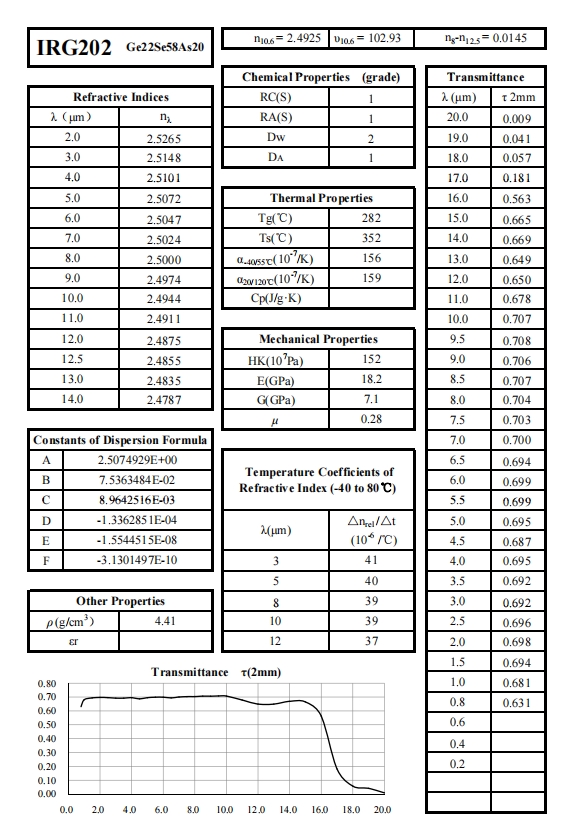

2. IRG202

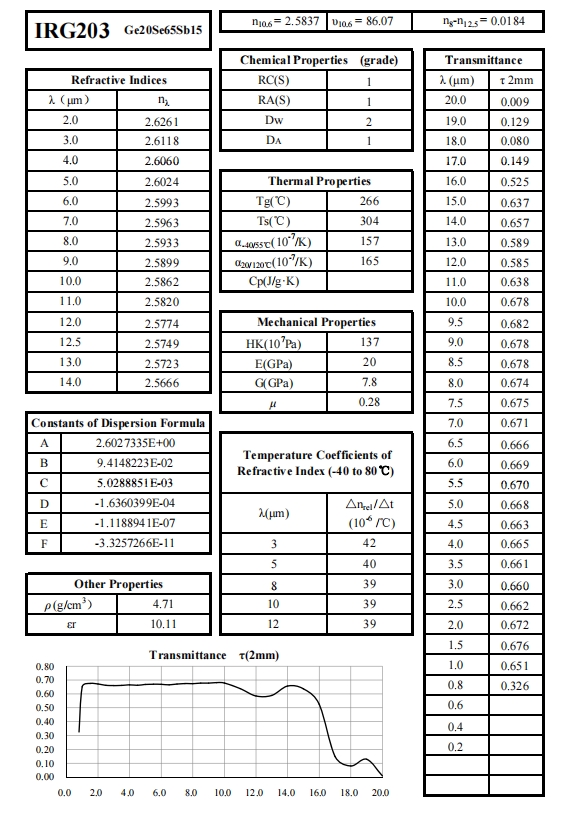

3. IRG203

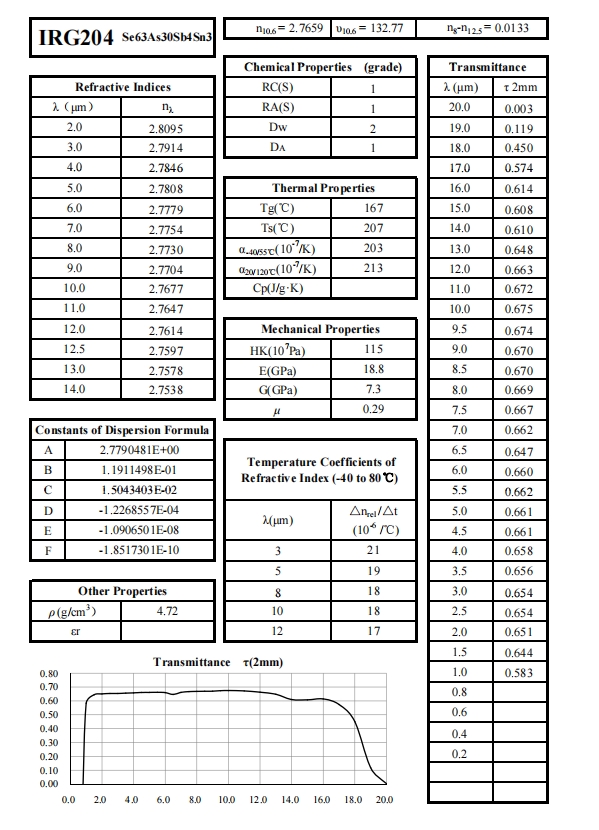

4. IRG204

5. IRG205

6. IRG206

7. IRG207

Related Products

Tags: Chalcogenide Glass