Optical Substrate Material Selection Guide

Part 1:

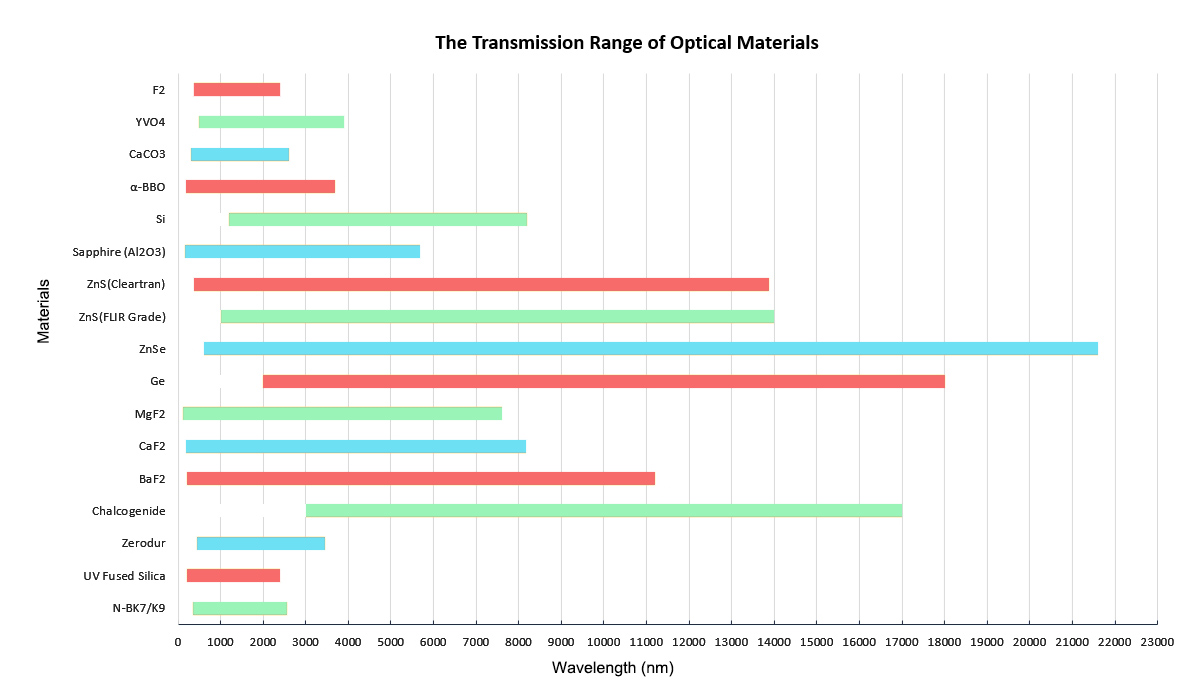

Below is a diagram showing the comparison of transmission wavelength range among different optical materials, you may use it as a guide while selecting optical products.

Part 2:

Below are some summarized introductions to the optical, chemical, mechanical, etc. properties of the common optical materials, including their advantages, weaknesses, and their befitting applications.

| Material | Characteristic | Optical Transmission and Coatings | Refractive Index |

| N-BK7/K9 Glass | The most common material for optical components is available in large amounts. Featuring Low bubble/inclusion content, and decent mechanical/chemical endurance. Often selected when high UV transmission of UV Fused Silica is not required. NBK7 and its equivalent K9 glass is also an excellent material for manufacturing mirror substrate, where metallic coatings (Aluminium, Silver, Gold) could be furnished. | 350nm-2200nm. High transmission in the visible and NIR range, in particular, suitable for producing precision optics operating in the visible wavelengths. When utilized as a mirror substrate, metallic coatings such as Enhanced Al, Protective Ag, and Au coatings are common. |

1.517 (at 587.76nm) |

| UV Fused Silica/JGS1 Glass | Wider transmission wavelength range (especially in the UV range) and better thermal stabilities, and homogeneities compared with N-BK7. Resistance to UV radiation and low levels of fluorescence. UV Fused Silica and its equivalent JGS1 glass is also an excellent material for manufacturing mirror substrate, and various kinds of coatings like broadband dielectric coatings, metallic coatings, etc could be implemented. | 200nm-2200nm. High transmission from UV to NIR range. Its moderate refractive index contributes to a higher overall transmission rate. When utilized as a mirror substrate, broadband dielectric coatings, metallic coatings, etc could be implemented. |

1.458 (at 587.76nm) |

| Zerodur Glass | A non-porous glass-ceramic sourced from SCHOTT featuring near-zero thermal expansion. The material also exhibits high CTE homogeneities across bulk volume and high chemical resistance, delivering reliable performance for high precision and demanding optics that are sensitive to thermal variations (e.g. large-aperture lenses for astronomical telescopes). Although consisting of micro-crystal distributed in the glass phase, Zerodur still retains the high machinabilities similar to other glass materials. | 450nm-3000nm. | 1.542 (at 587.76nm) |

| Chalcogenide Glass | A fine glass material for uses in the MWIR/LWIR region features low-temperature coefficients of refractive index (dn/DT), therefore could be utilized for the development of compact and lightweight optical passive athermalized lens assemblies in thermal imaging cameras. Its production cost is lower than germanium and could be processed with high efficiencies due to a lower softening point and mechanical hardness than other IR-transmitting crystals. | 3μm-14 μm. Common coating configurations are 3-5 micro or 8-12 micro AR coatings. | 2.4944 (at 10000nm) |

| Barium Fluoride (BaF2) | A popular optical fluoride for applications in the LWIR to far-infrared waveband (8-14micro) could be utilized as a viewport window in thermographies and infrared spectroscopes for fuel oil. Also the fastest scintillator materials. High resistance to water and intense radiation. Starts to degrade at temperatures above 500℃ in a moist environment, however, in an arid environment the limit could be raised to 800℃. | 200nm-11000nm. The transmission rate is above 90% within the interval of 500nm to 9000nm, and the transmission bandwidth extends about 1000nm more than CaF2. | 1.468 (at 1064nm) |

| Calcium Fluoride(CaF2) | A popular optical fluoride for applications in the UV to MWIR region. Polycrystal BaF2 is much more accessible, whilst the single-crystal form of BaF2 is rare and more expensive. Could be incorporated as optical components in thermal imaging cameras, and spectroscopes, and their high damage threshold makes them an excellent alternative for excimer lasers. On some occasions, its low refractive index even allows the exemption from anti-reflection coatings. More resistant to water than BaF2. | 180nm-8000nm. More transparent to shorter wavelengths than BaF2. On some occasions, its low refractive index even allows the exemption from anti-reflection coatings. |

1.428 (at 1064nm) |

| Magnesium Fluoride (MgF2) | An Ultraviolet to Infrared transmitting material, and is utilized for UV wavelengths (as UV windows, UV lenses, prisms, etc.) most time with its superior high transmission in the vacuum ultraviolet (VUV, 100-200nm) spectrum. The mechanical strength of MgF2 is also remarkable, making them durable in high-stress environments. In addition, due to its birefringence, MgF2 could also be used to manufacture polarizing optics such as waveplates. | 110nm-7500nm. Excellent transmission in the VUV region, the transmission rate is still above 80% as the wavelengths shift deeper to the UV region at 170nm. | ne=1.378 no=1.390 (at 587.6nm) |

| Germanium (Ge) | Extensive usage in the MWIR and LWIR wavelength range, like infrared thermal camera lenses. A high refractive index helps to reduce aberrations but also leads to high optical reflection (above 50% without AR coating) and therefore anti-reflection coatings are required. Its temperature of refractive index (dn/dT) is large, resulting in significant thermal defocus effect, and therefore athermalization design is needed. Its optical transmission will plummet at temperatures above 90℃, however, the mechanical hardness and chemical resistance (except acid) of Ge are excellent. Its large weight might become an issue for weight-sensitive designs. | 2000nm-16000nm. Wide transmission in the IR region and being opaque to visible lights. AR coatings are often required attributed to their large refractive index. | 4.004 (at 10600nm) |

| Zinc Selenide (ZnSe) | Exceedingly wide transmission range, large refractive index, and low absorption in the IR spectrum make them suitable to be applied as mirrors and focusing lenses for high-power CO2 laser (In fact, ZnSe is the material with the lowest absorption for 10.6nm CO2 laser output). However, zinc selenide is soft and susceptible to scratches, therefore is not recommendable for harsh environments. When cleaning, make sure you wear a glove, and the optics should be handled with due care. | 600nm-21000nm. The high transmission rate in the 600-16000nm spectrum. AR coatings are often required attributed to their large refractive index. | 2.403 (at 10600nm) |

| Zinc Sulfide (ZnS) | There are in general two kinds of Zinc sulfide, Foward Looking Infrared (FLIR) Grade ZnS made using chemical vapor deposition (CVD), and Multispectral ZnS (sold under the name Cleartran), which is water clear form of ZnS obtained using the hot isostatic pressing technique. In Comparative terms, FLIR grade ZnS has greater harness endurable to harsh conditions, and excellent optical transmission in the 8-12 LWIR region, hence is often engaged in the production of IR windows and front lenses for thermal imaging cameras. Whilst Multispectral ZnS (Cleartran) features lower hardness and high transmission across the visible, MWIR, and LWIR wavelength range, therefore Cleartran could be applied to multi-waveband usages (laser rangefinder). | FLIR Grade ZnS: 1000nm-13000nm Multispectral ZnS (Cleartran): 370nm-13500nm |

FLIR Grade ZnS: 2.192 (at 10000nm) Multispectral ZnS: 2.20084 (at 10000nm) |

| Sapphire (Al2O3) | Excellent transmission from UV to NIR range. Sapphire could be processed into multiple kinds of optics including Infrared windows, lenses, and ball lenses. Unrivaled harness among optical materials allows the production of thinner substrates. High chemical inertia to acids, alkaline, and water, and temperature tolerance up to 1000℃ indicate that sapphire is suitable for extreme conditions. | 170nm-5500nm. The transmission rate is above 80% between 220nm and 4.5 micros. | no=1.75449 ne=1.74663 (at 10600nm) |

| Silicon (Si) | Excellent transmission in the Near-Infrared and Mid-Infrared spectrums. Featuring high chemical inertia and outstanding mechanical strength. It is often utilized to manufacture Infrared windows, IR lens substrates, and the substrate for optical filters. Its high thermal conductivities and light weight are also advantageous when incorporated as laser mirrors with weight-sensitive designs. | 1200nm-7000nm. | 3.423 (at 4580nm) |

| Alpha BBO(α-BBO) | Alpha BBO is a negative uniaxial birefringent crystal, which is the high-temperature phase of barium borate. The mechanical, chemical, thermal, and optical properties of alpha BBO and beta BBO are quite alike, which include high damage threshold, wide temperature bandwidth, high optical homogeneity, etc. except that there is no second-order nonlinear effect in alpha BBO, since it is symmetrical about the center so it can not be utilized as an optical nonlinear medium. However, alpha BBO exhibits a strong birefringent character over a wide transmission spectrum of 190-3500nm, which makes alpha BBO crystal a compelling material in applications located in the ultraviolet spectral region and various crystalline birefringent polarization optics such as Glan polarizers, Wollaston polarizers, Rochon polarizers, etc. Alpha BBO is, in particular, excellent for manufacturing UV polarizers because of its decent UV transmission rate and capabilities of wielding high power. | 190nm-3500nm. | ne=1.533,no=1.673 (at 587.6nm) |

| Calcite(CaCO3) | Calcite, equivalently called Iceland Spar, is a natural optical crystal exhibiting strong birefringence. The intense birefringent nature causes objects viewed through calcite in the sight to be doubled. A Danish scientist Rasmus Bartholin first discovered this phenomenon in 1669. With its transmission range from 300 to 2300nm, Calcite is an exceptional selection for manufacturing birefringent polarizers in the visible and NIR zones. It can also be designed as either a polarization splitter/combiner or as a polarizer element that removes the angled component of a beam of orthogonal polarization. | 300nm-2300nm. | ne=1.480,no=1.642 (at 1064nm) |

| Yttrium Orthovanadate (YVO4) | Yttrium Orthovanadate (YVO4) is a positive uniaxial crystal grown using the Czochralski method. It exhibits strong birefringence and a broad transmission wavelength(488-3400nm) range that extends into the infrared region, making the YVO4 crystal excellent for fabricating IR polarizers. In addition, YVO4 crystal also excels in terms of good temperature steadiness, and physical and mechanical properties. YVO4 is excellent for manufacturing crystalline birefringent crystals, but it is also a great synthetic substitute for Calcite (CaCO3) and Rutile (TiO2) crystals in manifold applications including fiber optic isolators and circulators, interleaves, beam displacers, and other polarizing optics. | 488nm-3400nm. | ne=1.959,no=2.166(at 1064nm) |

| F2 Glass | F2 is a SCHOTT flint glass code, which exhibits high refractive and low Abbe number(i.e. high chromatic dispersion). Due to the aforementioned reasons, F2 Glass is an excellent option for manufacturing equilateral dispersive glass in its transmission range of 385-2000nm. F2 Glass also has the merits of superb chemical inertia. | 385nm-2000nm. | 1.620@587.6 |

Tags: Optical Substrate Material Selection Guide