Scintillation Screens for X-ray Imaging

Introduction

In the world of medical diagnostics, industrial testing, and scientific research, the accuracy and clarity of imaging are paramount. Thanks to technological advancements, the utilization of scintillation screens has significantly enhanced the quality of X-ray imaging. To understand the incredible utility of these screens, let's delve into the working principle of scintillators, what exactly a scintillation screen is, their vital role in X-ray imaging, and the various scintillation materials employed in these screens.

The Working Principle of Scintillators

To appreciate the significance of scintillation screens, we must first comprehend the working principle of scintillators. At their core, scintillators are materials that emit light when exposed to ionizing radiation, such as X-rays or gamma rays. This emission of light, known as scintillation, occurs as a result of the interactions between the incoming radiation and the atoms within the scintillator material. The difference between fluorescence and scintillation is that scintillation is the emission of photons following the excitation of atoms and molecules by radiation (particle radiation). fluorescence is the emission of light by a substance that has absorbed light or another electromagnetic radiation of a different wavelength.

The scintillation process begins with the absorption of high-energy photons, which excite electrons in the material to higher energy states. As these excited electrons return to their ground states, they release energy in the form of visible light. The intensity of the emitted light is proportional to the energy of the incident radiation, making scintillators an invaluable tool in radiation detection and imaging.

What Is a Scintillation Screen?

A Scintillation Screen is scintillation crystals processed into thin plates. Scintillation screens are crucial components in various imaging applications, particularly X-ray imaging. It serves as the interface between the incoming radiation and the imaging device, enabling the conversion of X-ray photons into visible light. This emitted light can then be detected, measured, and converted into detailed images for diagnostic, research, or industrial purposes.

What characteristics should a good scintillator have?

A good scintillator should exhibit:

- High efficiency of energy conversion into light

- Emission spectra matched to the spectral response of the photon detector (e.g. CCD camera)

- Excellent dynamic range and good linearity between the incident particle flux and the light output

- Low absorption of emitted light inside the bulk material

- Short decay time for observations of time-dependent beam size variations and reduction of saturation effects

- Good mechanical and thermal properties

- High radiation resistance to prevent damages

Scintillation Screen and X-ray Imaging

X-ray imaging is a groundbreaking technology that has transformed the way we visualize the human body, inspect industrial components, and conduct scientific research. This powerful imaging technique relies on X-rays, a form of electromagnetic radiation, to penetrate objects and create detailed images of their internal structures.

X-rays can be divided into two categories: hard X-rays and soft X-rays. X-rays with high photon energies above 5–10 keV (below 0.2–0.1 nm wavelength) are called hard X-rays, while those with lower energy (and longer wavelength) are called soft X-rays.

Scintillation screens play a vital role in X-ray imaging systems. They are strategically placed behind the object being imaged, where they intercept the X-rays after they have passed through the subject. The scintillator material in the screen absorbs the high-energy photons, causing the excitation of electrons within the material. As these excited electrons return to their ground states, they release energy in the form of visible light. This light is then detected by a photodetector, which converts it into an electrical signal. Subsequently, the signal is processed and used to create a high-resolution image, providing valuable insights into the internal structures of the subject. The intensity and wavelength of the emitted light are directly proportional to the energy of the incident X-ray photons. This property allows scintillators to serve as efficient energy converters.

Different Scintillation Materials for Imaging Screens

Scintillation screens can be crafted using various scintillator materials, each with unique properties and advantages. Some common scintillator materials used in imaging screens include:

Sodium Iodide (NaI): Sodium iodide scintillators are widely used due to their high light output and efficiency in converting X-ray photons into visible light.

Cesium Iodide (CsI): CsI screens offer excellent spatial resolution, making them ideal for medical imaging applications where fine details are crucial.

Gadolinium Oxysulfide (GOS): GOS scintillators are valued for their high stopping power, making them suitable for industrial radiography.

Lanthanum Bromide (LaBr3): LaBr3 screens are known for their fast response time, which is advantageous in applications requiring quick image acquisition.

YAG:Ce and LuAG:Ce: the crystals provide excellent properties for imaging with lower energies. The emission spectra of both crystals make them ideal for consecutive photodiode and avalanche photodiode readouts.

YAP:Ce: the crystal is suitable for readout in the UV.

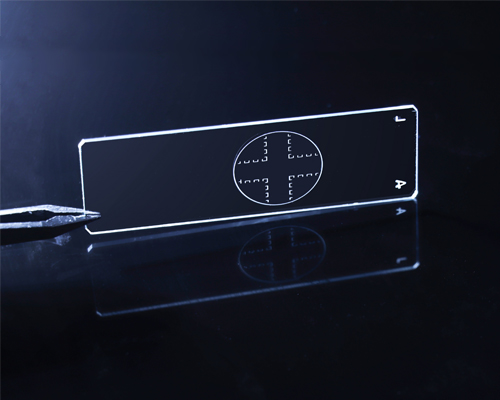

Hangzhou Shalom EO offers YAG(Ce), YAP(Ce), GAGG(Ce), and LuAG(Ce) scintillation screens, the scintillation screens are exceptional options for soft X-ray imaging. Our scintillation screens deliver high resolutions for low-energy X-ray imaging. With advanced production techniques, we are capable of manufacturing ultra-thin scintillation screens and engraving coordinate lines on the screens.

Customized Scintillation Screens from Shalom EO, Click on the blue text to learn more

Conclusion:

In conclusion, scintillation screens have revolutionized X-ray imaging by enabling the efficient conversion of ionizing radiation into visible light. Their working principle, crucial role in imaging, and the variety of scintillation materials available make them an indispensable tool in the fields of medicine, industry, and scientific research. As technology continues to advance, scintillation screens will likely play an even more significant role in improving the accuracy and quality of imaging in various domains.

Tags: Scintillation Screens for X-ray Imaging