What are Thermal Camera Lenses

This article is a basic introduction to Thermal Camera Lenses, which refers to the lens components used for infrared thermal imaging.

First of all, before understanding the thermal camera lenses, we must figure out what thermal imager and thermal camera are, and how these two work. Objects with a surface temperature higher than absolute zero (-273°C) emit infrared magnetic radiations (that is, the radiations with wavelengths beyond 700nm, but above 1000 microns) outward. Unlike a visible camera which produces images by capturing visible light, an infrared imager is a device that forms the image by detecting the temperature of the object. Because the thermal imaging system detects heat rather than light, it can be used 24/7, moreover, it is a piece of passive equipment, and there is no extra radiation, so it does not expose the user's location.

The infrared spectrum can be divided into five categories according to different wavelength ranges: Near Infrared (NIR), wavelength range 0.75 microns-1.4 microns; Short Wave Infrared (SWIR), wavelength range 1.4 microns-3 microns; Mid Wave Infrared (MWIR), wavelength range 3 microns-5 microns; Long Wave Infrared (LWIR), wavelength range 8 microns-12 microns; and far-infrared, which ranges from 15 microns-1000 microns. Among them, The MWR and LWIR spectral regions are the two major wavelength ranges for thermal imaging. MWIR and LWIR radiation could penetrate the atmosphere and produce images detecting the temperature difference of the objects, helping us to scout the environments better in fogged weather or at night.

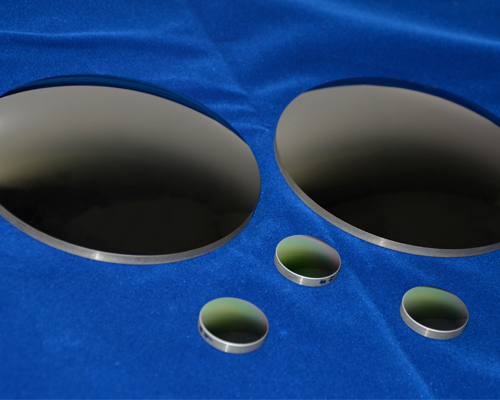

Figure 1. This picture exhibits Shalom EO's Thermal Imaging Lenses as an example

To be more specific about the working principle, a thermal imager or camera uses optics to focus the infrared radiation from the objects in the scene onto an infrared detector, and then the digital data from each detector element are converted into a standard video format that can be viewed on a standard video monitor or recorded on a videotape. The detectors inside the thermal imagers are divided into two categories: Cooled Photon (Quantum) Detectors and Uncooled Thermal Detectors. Detectors of thermal imagers exist to receive the thermal radiations entering via the thermal camera lenses and to produce visual representations of the temperature differences. Therefore the self-heating of the detector will increase the thermal noise and result in a loss of sensitivities. A cooled Photon detector produces a direct electrical effect after absorbing infrared radiation, while a thermal detector produces a temperature change after absorbing the infrared waves, and generating an electrical effect. The material properties of the detectors affect how temperature changes induce the electrical effect. In comparative terms, cooled photon detectors are more sensitive. Cooled photon detectors are often integrated with a cooler to maintain the detector at -130 degrees Fahrenheit or less and maintain high sensitivities. Cooled Quantum Detectors are often incorporated into MWIR thermal imagers. An uncooled thermal detector, on the other hand, does not contain a temperature control gadget and might suffer from loss of sensitivities but will be much cheaper than a cooled detector and perform well enough at room temperature. For the most part, uncooled infrared FPA detectors/sensors are designed to match with Long Wave Infrared (LWIR) thermal imaging camera lenses operating at 8-12 micro.

When designing and manufacturing infrared camera lenses, materials different from those of visible lenses are chosen. The material should be transparent to the infrared wavelength range of interest. For example, silicon might not be as a good choice as germanium when producing LWIR Thermal Camera Lenses since silicon is opaque to wavelengths above 7000nm. Apart from materials, it is important to weigh and balance other factors such as field of view, weight, dimension, and the focusing mechanisms of the infrared camera lenses as well.

Figure 2. A Single Infrared Germanium Lens from Shalom EO

A set of finished thermal camera lens modules constitutes more than one single lens. A group of single IR lens components of various materials (e.g. Materials with complementing coefficient of thermal expansions are often combined into one lens module to realize passive optical athermalization) forms, and functions (e.g biconvex to collect and converge thermal radiations while balancing out spherical aberrations, plano-concave lenses to diverge collimated radiations or collimate converging radiations, achromatic doublets to eliminate chromatic aberrations, etc) is selected and engineered with deliberations to cater to the intentions of the lens assemblies.

Apart from the materials, there are also other critical parameters that define the functions and capabilities of infrared lens assemblies, including Sensor Size and Resolution, Depth of Field (DOF), Focal Length, Field of View (FOV), f-number, Transmission of Materials, Image Distortion, Modulation Transfer Function (MTF), Spherical Aberration and Coma. Read more in our technical article Lens Selection Tutorial to learn more about the definition of these glossaries.

Thermal camera lenses can be classified according to the working wavelengths, for example, SWIR thermal camera lenses working for the 0.9-1.7 micro spectral range, MWIR thermal camera lenses operating for infrared radiations between 3-5 micros, and LWIR thermal camera lenses working in the 8-12 micro spectral ranges.

The short-wave infrared (SWIR) imaging shows more details and better contrast because SWIR light interacts with objects in a similar manner to visible wavelengths in that the photons are reflected from the object. However, this trait contributes to the problem that the SWIR lens relies more on the visible illumination condition. SWIR thermal camera lenses are often coupled with InGaAs (Indium Gallium Arsenide) sensors. SWIR thermal imaging reveals more details that are invisible to the human eye, serving critical functions in the field of agriculture and forefront biological research.

The mid-wave infrared lenses detect radiations emanating from heated objects and are preferred options for long-range detection and surveillance. Besides, because MWIR thermal cameras often utilize cooled photon sensors, (often FPA detectors made of HgCdTe or InSb), which exhibit higher sensitivities than the uncooled thermal imagers often utilized in LWIR thermal cameras, MWIR thermal imaging, as a subsequence, has better capabilities to reject thermal noise, and clutter and to discriminate similar temperatures, elevating the target contrast in the image. MWIR lenses are also less susceptible to atmospheric absorption than LWIR lenses, making MWIR lenses thermal lenses recommendable for a wide range of applications, including defense, (night vision and target detection, UAS, counter-UAS), industrial-process monitoring (oil and gas detection). One major drawback of MWIR lenses is that MWIR tends to be expensive.

The LWIR thermal camera lenses are the more conventional option for thermal imaging due to their affordable price and the fact that LWIR lenses work well when capturing objects at room temperature. LWIR radiations are also less susceptible to smoke and aerosol and hence are more advantageous than MWIR imagers in contexts like firefighting. However, for users whose prior requirement is long detection and sharp images, LWIR lenses are disadvantaged because for LWIR radiation there is a severe problem of signal attenuation due to long distances or other disrupting factors such as molecules in the air.

Thermal imaging camera lenses can also be classified according to the optical structure of the lenses, such as single FOV thermal camera lenses, dual FOV thermal camera lenses, continuous zoom thermal camera lenses, athermalized thermal imaging lenses, fisheye and super wide angle thermal camera lenses, microscope thermal camera lenses, the detailed explanations of each lens type are as follows:

Athermalized thermal imaging lenses are thermal camera lenses engineered with the purposeful attenuation of the thermal defocus effect, where the focus position on the optical axis changes because of the variation in the refractive indices of the optical materials of the lenses due to temperature changes. In Shalom EO, we offer passive athermalized thermal camera lenses.

Field of view (FOV) is defined as the maximum angle at which the device is sensitive to electromagnetic radiation. Single FOV thermal camera lenses and dual FOV thermal camera lenses are thermal camera lenses that provide a fixed FOV or two FOV. In real life, so that users can obtain a clear focus for the target with more convenience, the lenses are integrated with manual or motorized focusing mechanisms to enable mild adjusting of the focal lengths, and hence the nominally fixed FOVs of the lenses are also adjustable to a slight extent.

Zoom Lenses are lens assemblies providing a broad scope of variable focal lengths within certain designed boundaries, as the opposite of prime lenses with fixed focal lengths. A set of Continuous Zoom (CZ) lenses can support continuous shifting of focal lengths to generate focused images throughout a wide range of distances from close-ups to remote positions without the bother of changing the working distance. The zooming function can be very instrumental for thermal camera lenses in various application scenarios with the advantage of providing users with flexible visual experiences to adjust the magnification at will.

Fisheye Lenses and Super Wide Angle Lenses are lenses that deliver ultra-wide angles of view that are much wider than that of the regular lenses, fisheye and super wide angle lenses also have much shorter focal lengths than those of the average lenses. There are no definite boundaries of focal length and FOV to differentiate fisheye lenses and super wide angle lenses, the major differences are that the front lens of fisheye lenses has a protruding parabolic like the real eye of a fish and that fisheye lenses produce extremely barrel distortion in the image which requires algorithm calculation corrections. (Click here to view a general guide about what fisheye lenses are.)

Microscope Thermal Lenses deliver outstanding thermal imaging capabilities at a microscopic scale, enabling users to delve into the temperature distribution of minute structures. With superior magnification and focusing capabilities, microscope thermal lens optics deliver clear and sharp images, facilitating in-depth analysis of fine object structures.

After establishing the basic concept of what thermal camera lenses are, you are prepared to delve deeper into the subject. Click here to view Important Specs You Must Know For Infrared Thermal Imaging Lenses, where Shalom EO offers thorough explanations of the important specifications like image resolution, FOVs, f-number, flange, etc., and their implications in the context of thermal camera lenses.

Related Articles

Tags: What are Thermal Camera Lenses