LWIR Imaging VS MWIR Imaging, Which is Better?

Introduction:

There has been a long-term debate over the superiorities of Long Wave Infrared (LWIR) and Mid Wave Infrared (MWIR) Infrared Imaging. It’s impossible to tell which of them is better, but in this article we will guide you through a thorough evaluation of the pros and cons of LWIR and MWIR imaging, comparing the emittance and thermal contrast in the two spectral regions, the impact of climate, thermal effects, LWIR and MWIR lenses, costs. so that you might be able to choose the right kind of camera and thermal camera lenses which suit your application best.

In our last article What are Thermal Camera Lenses, we learned about different infrared spectral bands. The infrared spectrum can be divided into five categories according to different wavelength ranges: Near Infrared (NIR), wavelength range 0.75 microns-1.4 microns; Short Wave Infrared (SWIR), wavelength range 1.4 microns-3 microns; Mid Wave Infrared (MWIR), wavelength range 3 microns-5 microns; Long Wave Infrared (LWIR), wavelength range 8 microns-12 microns; and far-infrared, which ranges from 15 microns-1000 microns.

The MWR and LWIR spectral bands are the two major wavelength ranges for thermal imaging. MWIR and LWIR spectral bands are referred to as Thermal Infrared because MWIR and LWIR radiation could penetrate the atmosphere (that is, atmospheric obscurants cause much less absorption and scattering in the MWIR and LWIR bands than in the visible and SWIR band) and produce images without the need of an artificial light source, thus being utilized for passive thermal imaging. MWIR and LWIR imagers could form images according to the temperature difference of the objects, therefore providing valid imaging functions regardless of the luminous conditions. Thermal imagers are also more tolerant to smoke, fog, and dust than common visual imagers.

Flux and Thermal contrast:

Flux refers to the total thermal emission from the target object and the background. According to Planck’s Law, the higher the temperature, the higher the spectral radiant emittance (at all wavelengths) and the shorter peak wavelength of the emissions. As shown in figure one, under the normal atmospheric temperature of 300K, the peak wavelengths of emission reside at the 8-12 micron LWIR wavelengths. In other words, terrestrial objects (above absolute zero) emit heat most in the LWIR region.

Figure 1. Blackbody Emission

The technicolored area in the graph indicates the visible spectrum and the orange and red areas indicate MWIR and LWIR spectral regions. As we could perceive, at the normal temperature of 300K, the emission peak sits in the LWIR zone. As temperature rises the emission peak starts moving towards shorter wavelengths, and at about 1000K, the emission peak sits in the MWIR zone.

Remember thermal imagers or cameras focuses and transmit the thermal radiation emitted, and form a monochrome image correspondent to the heat differences. The higher the temperature, the more the thermal radiation, and the brighter the image, while cooler areas are represented using dark shades(There are also colored thermal cameras, where hot regions appear in warmer colors and cool regions appear in cool colors). It is obvious that a larger volume of flux helps to increase the sensitivities of imagers in ideal conditions. This implies LWIR imagers and cameras can handle well most of the normal circumstances (“normal” here means the environment is under an atmospheric temperature of 300K.)

At higher temperatures, the emission peak shifts to short wavelengths, there is the reason that MWIR thermal imagers work better in high-temperature environments (e.g. missile launching). Also, because MWIR thermal cameras often utilize cooled photon sensors, which exhibit higher sensitivities than the uncooled thermal imagers often utilized in LWIR thermal cameras, MWIR thermal imaging, as a subsequence, has better capabilities to reject thermal noise, clutter and to discriminate similar temperatures, elevating the target contrast in the image. MWIR thermal imaging, in particular, outperforms LWIR when it comes to long-distance operations, situations in which the thermal radiations reaching the sensors are attenuated due to the long path, resulting in greater difficulties to differentiate targets from nuisance as both might appear blurred on the imaging screen. MWIR imaging presenting higher target contrast, on such occasions, boosts the ease of recognition and identification of targets in distant areas. and is more reliable. Therefore, most clients with prior requirements of long-distance and sharper images select MWIR thermal cameras rather than LWIR thermal cameras.

Atmospheric Windows and the Effects of Climates:

Thermal radiations have to travel through the atmosphere to reach the imager. Since the atmosphere is not a vacuum, but rather consists of a mix of different gases (such as nitrogen, CO2, and O2) and particles (dust, dirt, vapor), it absorbs, reflects, refracts, and scatters electromagnetic radiations.

The transmission rate through the atmosphere varies with the spectral region. The wavelength regions where the transmission rates of electromagnetic radiation through the atmosphere are high are called Atmospheric Windows.

Figure 2. Atmospheric Windows

Different obscurants in the atmosphere also react with differences in the spectral regions. So it is important to consider the atmospheric elements while selecting your thermal imager. In general, the absorption of MWIR radiations in vapors is much less significant than for the LWIR radiations. As mentioned above, MWIR thermal imaging cameras are also exceptional for high-temperature environments due to the nature of thermal emission. Therefore MWIRs are more advantageous in humid and hot ocean climates. For instance, if your purpose is coastal surveillance, an MWIR camera is a more recommendable option. Whilst because the widest atmospheric window is located between 8-12 microns, LWIR radiations have superior transmission rates in most contexts and therefore LWIR cameras are fit for the imaging of most terrestrial objects at normal temperatures. LWIR radiations are also less susceptible to smoke and aerosol, hence are more advantageous than MWIR imagers in contexts like battlefield and fire fighting. So for instance, if you are looking for an infrared gun sight, an LWIR thermal imager might be better (However, in applications like defense and warfare, sometimes a certain detection range is required. In that case, MWIR cameras are more excellent than LWIRs.)

LWIR Lenses VS MWIR Lenses:

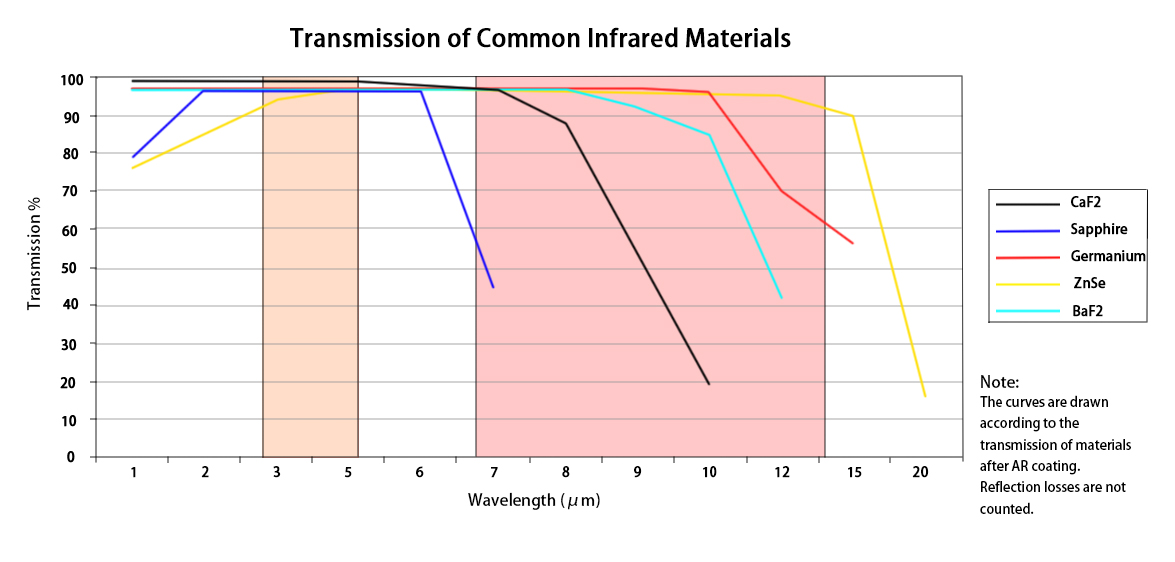

Just like visual camera lenses must be transparent to visible lights, thermal camera lenses must be transparent to certain infrared spectral regions. LWIR Thermal Camera Lenses are therefore manufactured using materials that exhibit excellent transmission in the 8-12 micron LWIR wavelength range, and MWIR Thermal Camera Lenses are made from materials that are transparent in the 3-5 micron MWIR wavelength range.

Figure 3 below shows some of the prevalent infrared lens materials and their transmission curves (Note that the curves are drawn according to the transmission rates after proper AR coating, so surface reflection losses are not included). As we could see from the figure, the common optical materials for LWIR Lenses include Germanium (Ge), Zinc Selenide (ZnSe), etc. (there are also other superb LIWR materials that are not shown in the figure like ZnS, Chalcogenide Glass, GaAs). Whilst conventional MWIR optical materials include Barium Fluoride (Baf2), Calcium Fluoride (CaF2), Sapphire(Al2O3), Ge, ZnSe, etc. (other MWIR materials absent in the figure: Silicon, ZnS, etc.) Sometimes a mix of different materials are utilized in one lens assemblies to achieve the desired design results (For example, optical passive athermalized lenses consists of lenses made from materials with complementary thermal-optical properties to balance out the thermal defocusing effects).

Figure 3. A comparison graph showing the transmission of some common IR lens materials. Note that the curves are drawn according to the transmission of materials after AR coating.

Figure 4. The left is a set of Continuous Zoom LWIR Thermal Lenses from Shalom EO. The right is a set of Continuous Zoom MWIR Thermal Lenses from Shalom EO.

Shalom EO has developed a state-of-the-art production of LWIR and MWIR thermal camera lenses for over a decade including lens structure design, CNC fabrication and diamond turning polishing, lens assembling, rigorous in-house inspection and IP67 sealing. Our capabilities are both superior in terms of large-size lens availabilities and long focal length performances. The LWIR CZ lenses provide a maximum 13X zoom ratio, while the MWIR CZ lenses exhibit even better long-range detection functions with a maximum zoom ratio of 20X.

Besides, Shalom EO also offers various kinds of Thermal Camera Lenses including Athermalized Lenses, Super Wide Angle and Fisheye Lenses, Single FOV Lenses, and Dual FOV Lenses. Click to learn more.

Detector Sensitivities and the f-Number:

There are two main kinds of detectors in the current thermal camera market: Cooled Photon Detectors (also called Quantum Detectors), which are often assembled with coolers to maintain the detector at cryogenic temperatures, and Uncooled Thermal Detectors, which are more affordable but less sensitive with the lack of coolers.

Since thermal imagers form images from visualizing the heat, the self-heating of the thermal camera creates thermal noise and leads to confusion about the target thermal signals. The result is the increase of NETD(Noise Equivalent Temperature Difference) and loss of sensitivities. A cooled photon detector, therefore, is much more sensitive than uncooled thermal detectors.

MWIR imagers often incorporate cooled detectors (e.g. HgCdTe detectors, Quantum Well detectors, Stibide detectors), whilst LWIR imager often utilizes uncooled detectors (e.g Vanadium Oxide detectors, InSb FPA).

The f-number or f stop, or f/# is a measure of the light gathering power of a camera, in the case of thermal cameras, the thermal radiation gathering power. f number=Focal Length of Camera Lens/Diameter of the Lens Aperture. A cooled detector with higher sensitivities allows higher f-numbers (and hence allows tinier lens apertures), whilst an uncooled detector with lower sensitivities should have low f-numbers (hence larger apertures to ensure enough radiation to enter) if the camera is to match the same focal length with the former. Therefore, the MWIR Thermal Camera Lenses could be made much more compact than LWIR Thermal Camera Lenses, saving the lens production cost and meanwhile reducing the weight of the entire camera in accord with the lightweight and compact-volume trend in the thermal camera market.

In similar manners, an MWIR thermal camera lens of the same aperture with an LWIR thermal lens could have longer focal lengths than the LWIR lens because of the higher f-number allowed.

Costs:

LWIR thermal imaging cameras, utilizing uncooled detectors, tend to be cheaper than MWIR thermal imaging cameras. And since LWIR are capable of coping with most of the thermal imaging applications, LWIR imaging is the more routine and economical option.

MWIR cameras, on the other hand, often incorporates cooled photon detectors (which are quite expensive), MWIR thermal imaging cameras tend to be more valuable than LWIR cameras. However, with the advantages of high image qualities, long-range detection capabilities, and superior performance in some particular situations (humid weather, high temperature), MWIR thermal camera could be worth the price.

Applications in C-UAS

Counter-Unmanned Aerial Vehicles or C-UAS/C-UAVs are specific techniques designed to detect, track, interrupt, or even wreck the drone to prevent unauthorized trespass of drones into certain areas. In these C-UAS facilities, various approaches are incorporated to monitor the aerial space and spot suspicious targets, including radar, visual cameras, and LWIR, MWIR, and SWIR thermal cameras. Passive LWIR and MWIR thermal imaging are two excellent approaches to realizing C-UAS with high environmental reliabilities, substantial long-distance capabilities, and exceptional abilities to tackle anti-detection tricks. You might visit our technical article Passive Thermal Imaging and C-UAS to view a more thorough evaluation and assessment of LWIR and MWIR as Counter-UAS approaches.

Related Products

Tags: LWIR Imaging VS MWIR Thermal Imaging Camera