$280.00

Specifications:

| Material | Quartz+MgF2 | Wavelength | 450-650nm |

| Retardation | λ/4 | Aperture | 18mm |

| Surface Quality | 20/10 S/D | Parallelism | <1 arc sec |

| Retardation Tolerance | < λ/100 | Damage Threshold | >500 MW/cm2 |

| Coating | AR coating | Mounted Diameter | 25.4mm (1 inch) |

450-650nm Achromatic Quarter Waveplate with Aperture 18mm and D1” mount, Code: 2081-001.

Hangzhou Shalom EO offers achromatic waveplates with quarter or half retardation made from single crystalline quartz and magnesium fluoride (MgF2), configured by high-quality AR coating. The two waveplates are either cemented by NOA61 (Norland Optical Adhesive 61) or air spaced. NOA61 is a high-performance adhesive with great bonding strength, high heat resistance, and excellent clarity to support optical applications under various operation conditions, where Shalom EO only applies the glue outside the clear aperture of the waveplates. Achromatic waveplates with an air gap design are coated on all faces and mounted on opposite sides of a spacer, placed within a cell, to form an air gap between the two quartz plates. The modules with air gap design have particularly promoted damage thresholds greater than 500MW/cm^2, and are suitable for high energy lasers. Both stoked and customized achromatic waveplates are available in Shalom EO with competitive prices and fast delivery services. Off-the-shelf modules for online shopping contain three conventional wavelength ranges: 450-650nm, 690-1200nm, 900-2000nm, spanning from visible to NIR spectral. Additionally, we also accept customized requirements where all the specifications could be tailored to suit your requests.

Curves:

1. Retardance via Wavelength

The graph above illustrates the responsiveness of retardance over wavelength change for 450-650nm λ/4 Achromatic Waveplate.

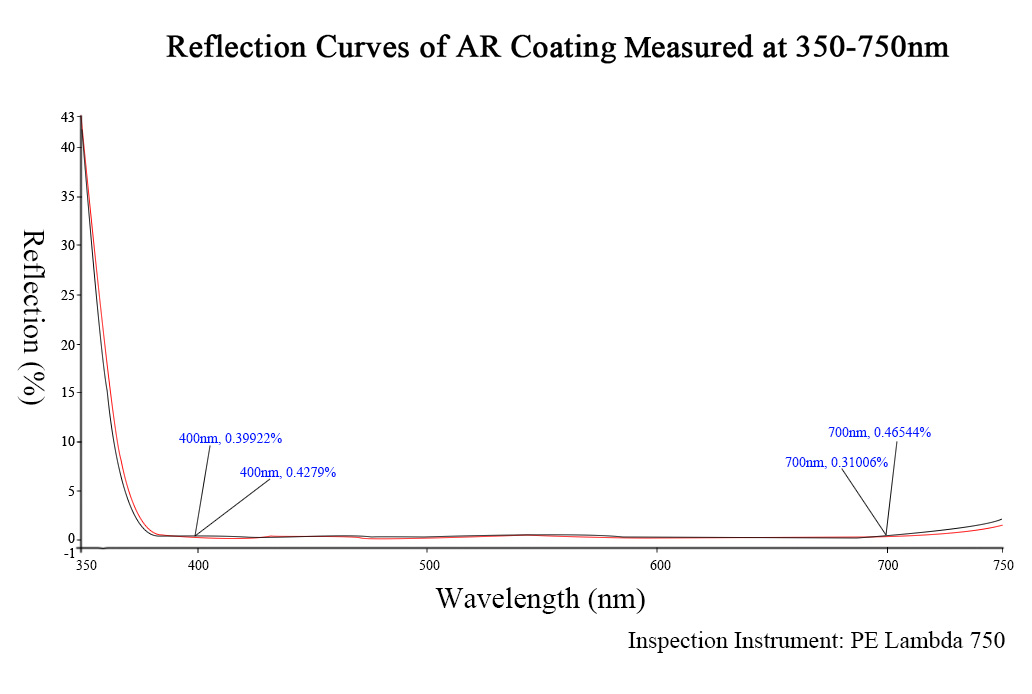

2. Reflection Rate of AR Coatings Measured at 350-750nm

The inspection is carried out using PE Lambda 750.